Air Filter Paper (for light car/heavy duty truck)

Application

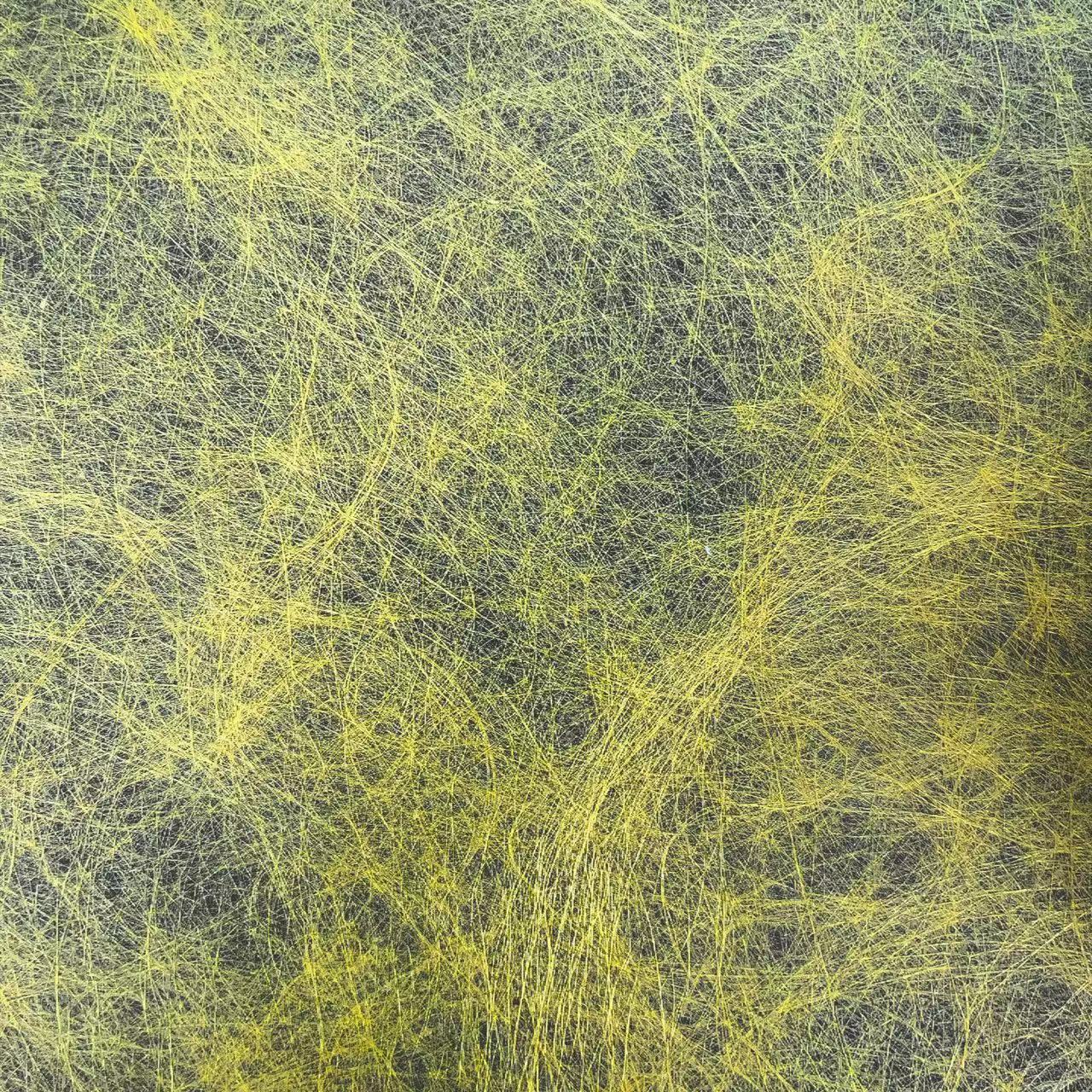

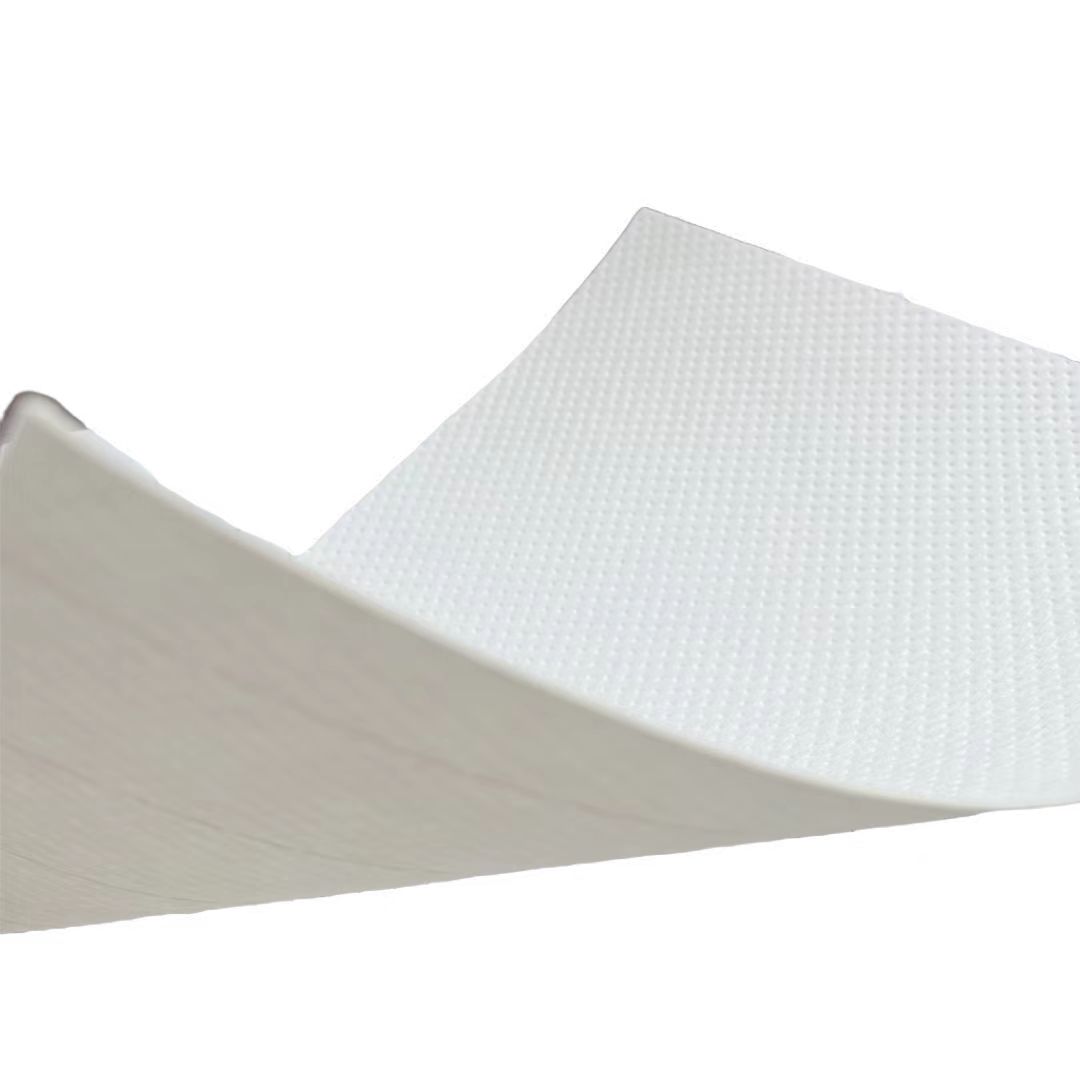

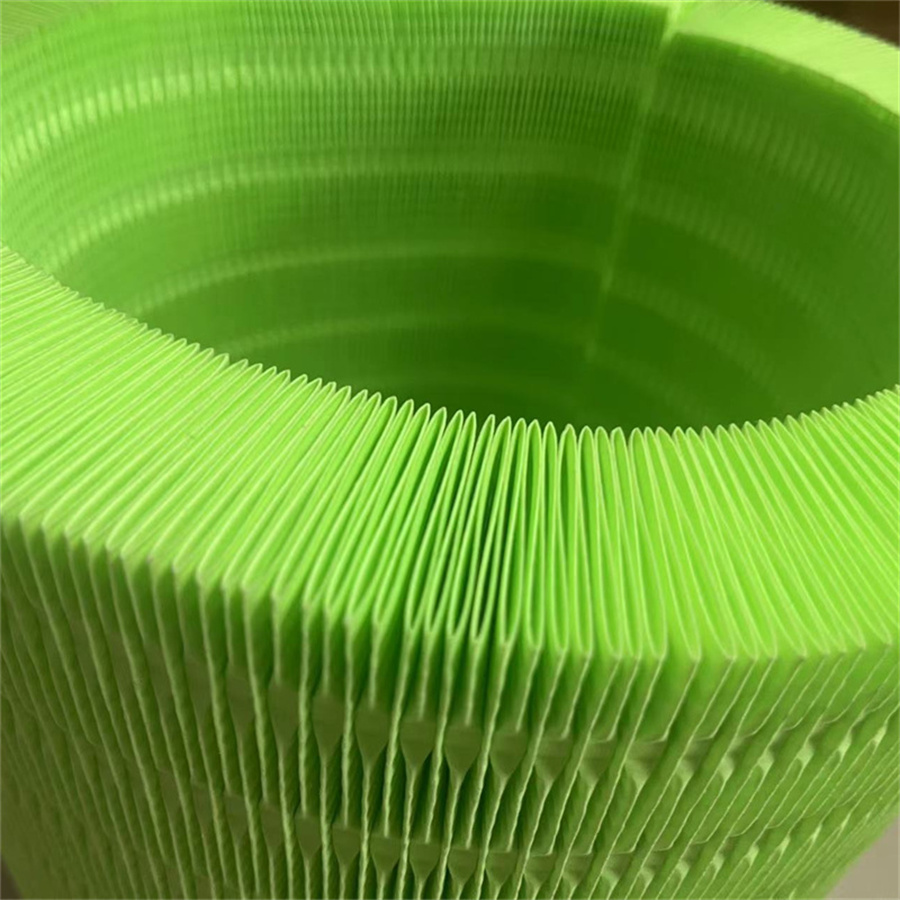

Air filter paper is applied to the air filter of automobile's engine. It will filtrate the dust and impurities when the air goes through media to enter in engine. Therefore, its filtration function keeps the engine full of clean air and protects it from the damage of impurities.

In order to get ideal filtration effect, the choosing of better performance filter media is significant. Our filter media possesses characteristics of higher filtration efficiency and longer using lifetime, cellulose and synthetic fiber can be added in the materials. Attitude determines altitude, to establish stable and long time relationship with customers is our unchanged principle.

Automobile filter paper is one of the main materials for the production of automobile filters, also known as automobile three filter paper, that is, air filter paper, oil filter paper, fuel filter paper, it is a resin impregnated filter paper, in the filter production line through the partial pressure, pressure wave, collection and curing processes made of filters, which in automobiles, ships, tractors and other internal combustion engines, play the role of the "lung" of the automobile engine. To remove the impurities in the air, oil and fuel, prevent the wear of the engine parts, extend its service life. There are many filter materials, such as cellulose, felt, cotton yarn, non-woven fabric, metal wire and glass fiber, etc., basically replaced by resin-impregnated paper filter, with the rapid development of the world automobile industry, filter paper as a filter material has been widely accepted by the world automobile filter industry. As early as 2004, the United States has listed automobile filter paper as one of the ten most promising paper species in the world.

Air Filter Paper For Light-Duty

Model number: LWK-115-160HD

| Acrylic resin impregnation | ||

| Specification | unit | value |

| Grammage | g/m² | 115±5 |

| Thickness | mm | 0.68±0.03 |

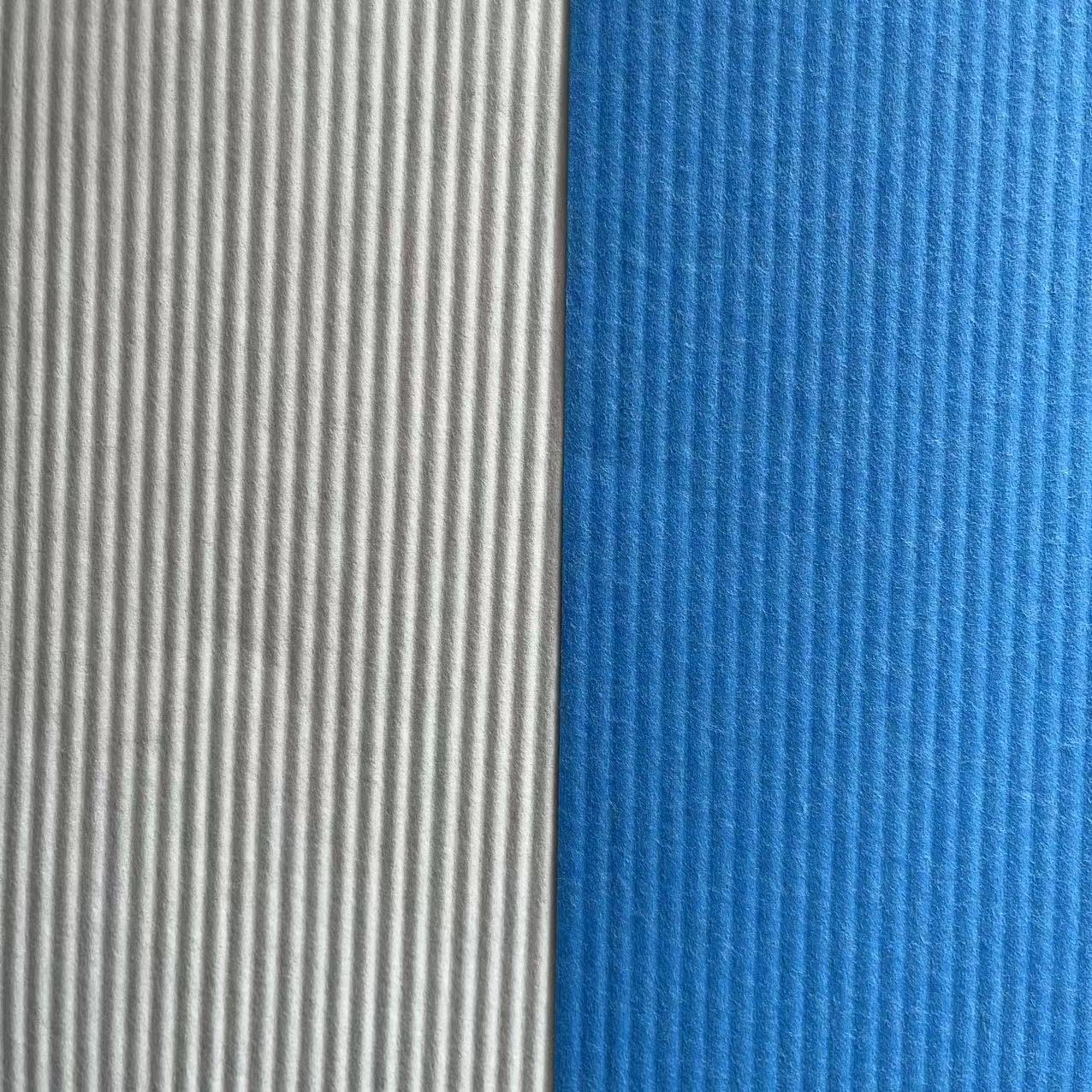

| Corrugation depth | mm | 0.45±0.05 |

| Air permeability | △p=200pa L/ m²*s | 160±20 |

| Max pore size | μm | 39±3 |

| Mean pore size | μm | 37±3 |

| Burst strength | kpa | 350±50 |

| Stiffness | mn*m | 6.5±0.5 |

| Resin content | % | 22±2 |

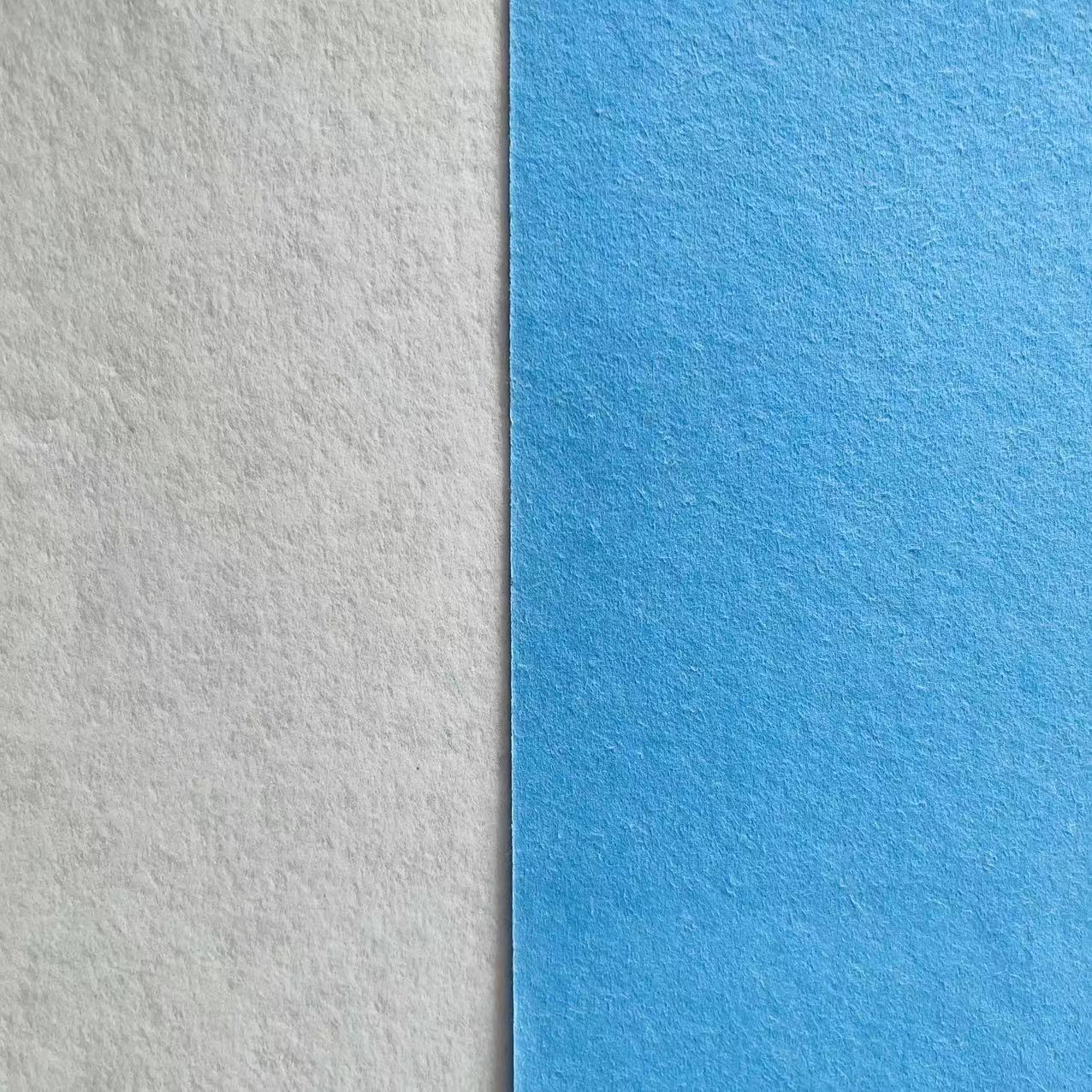

| Color | free | free |

| Note: color, size and each specification parameter can be changed as per customer’s requirement. | ||

Model number: LPLK-130-400

| Acrylic resin impregnation | ||

| Specification | unit | value |

| Grammage | g/m² | 130±5 |

| Thickness | mm | 0.43±0.05 |

| Corrugation depth | mm | plain |

| Air permeability | △p=200pa L/ m²*s | 400±50 |

| Max pore size | μm | 90±5 |

| Mean pore size | μm | 87±5 |

| Burst strength | kpa | 280±30 |

| Stiffness | mn*m | 6.0±0.5 |

| Resin content | % | 22±2 |

| Color | free | free |

| Note: color, size and each specification parameter can be changed as per customer’s requirement. | ||

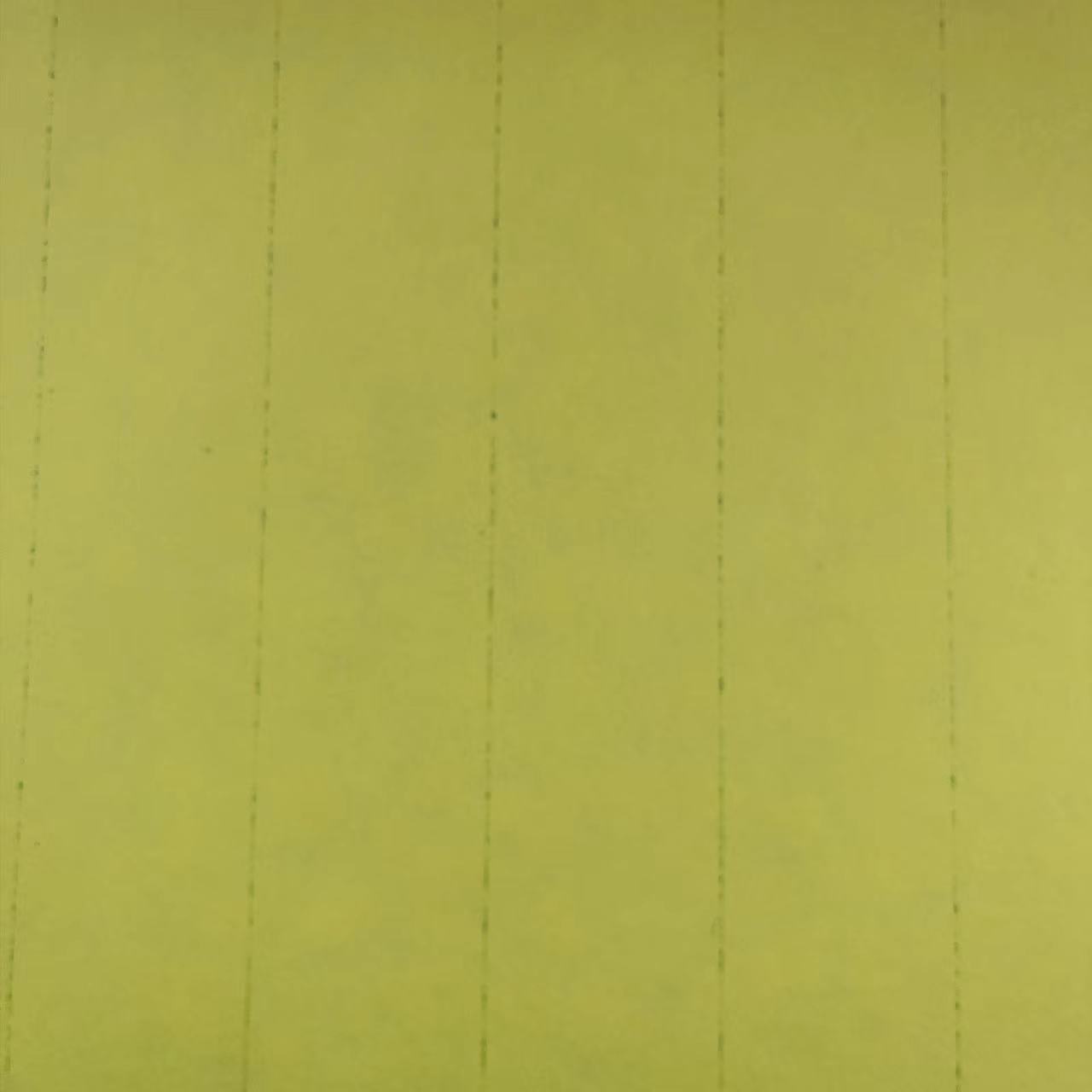

more options