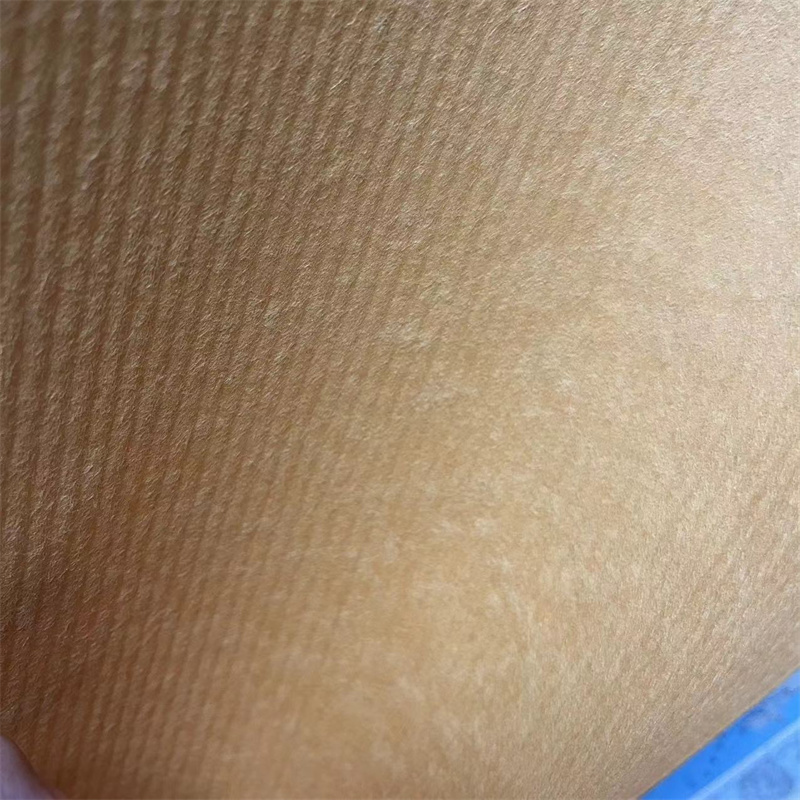

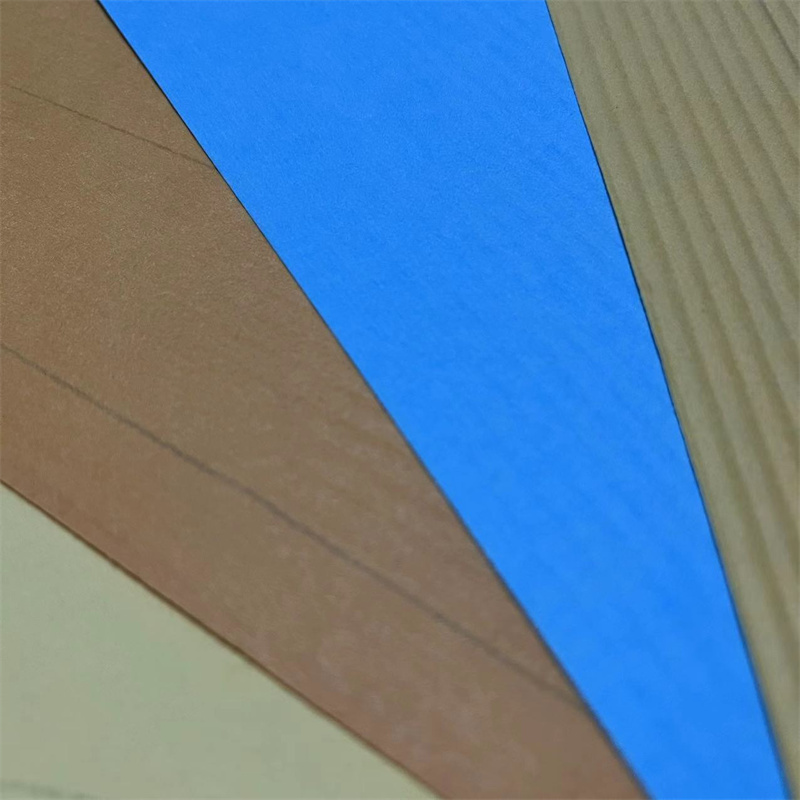

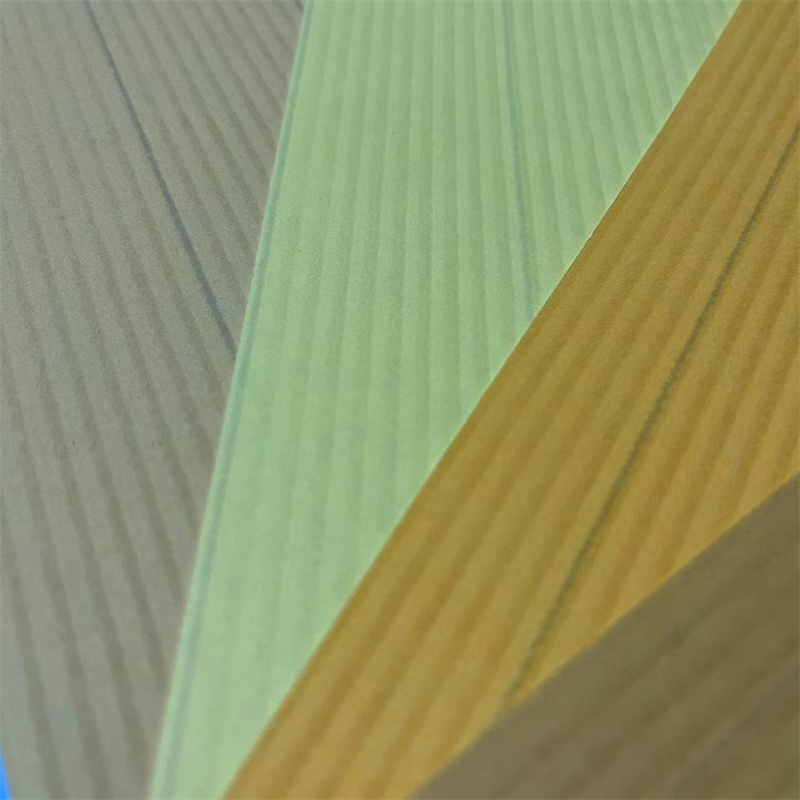

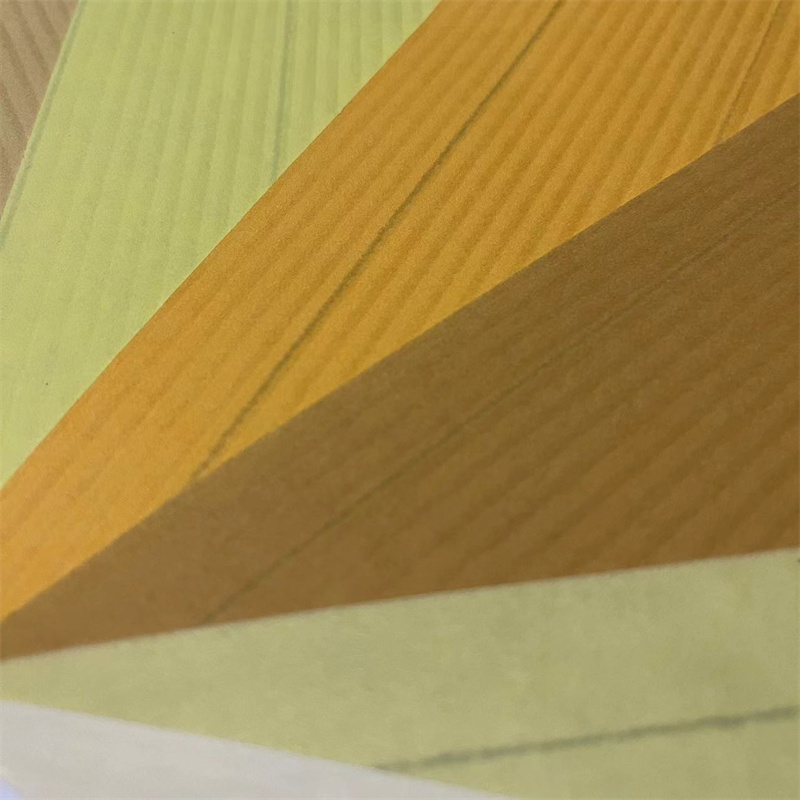

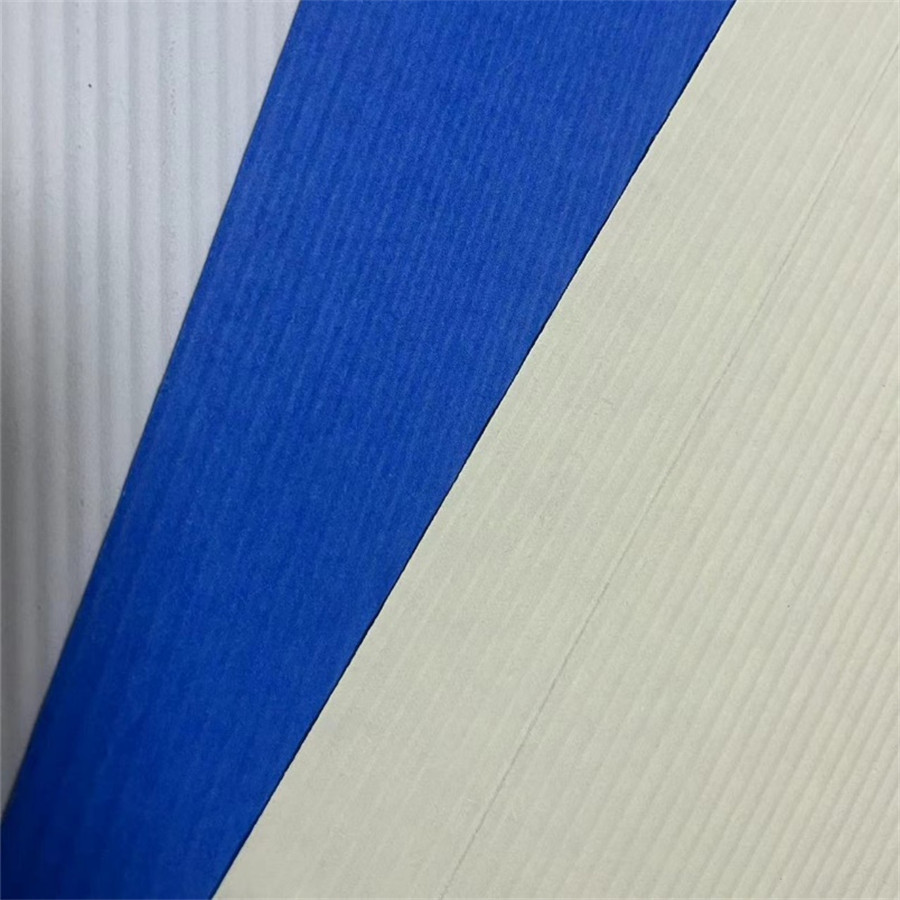

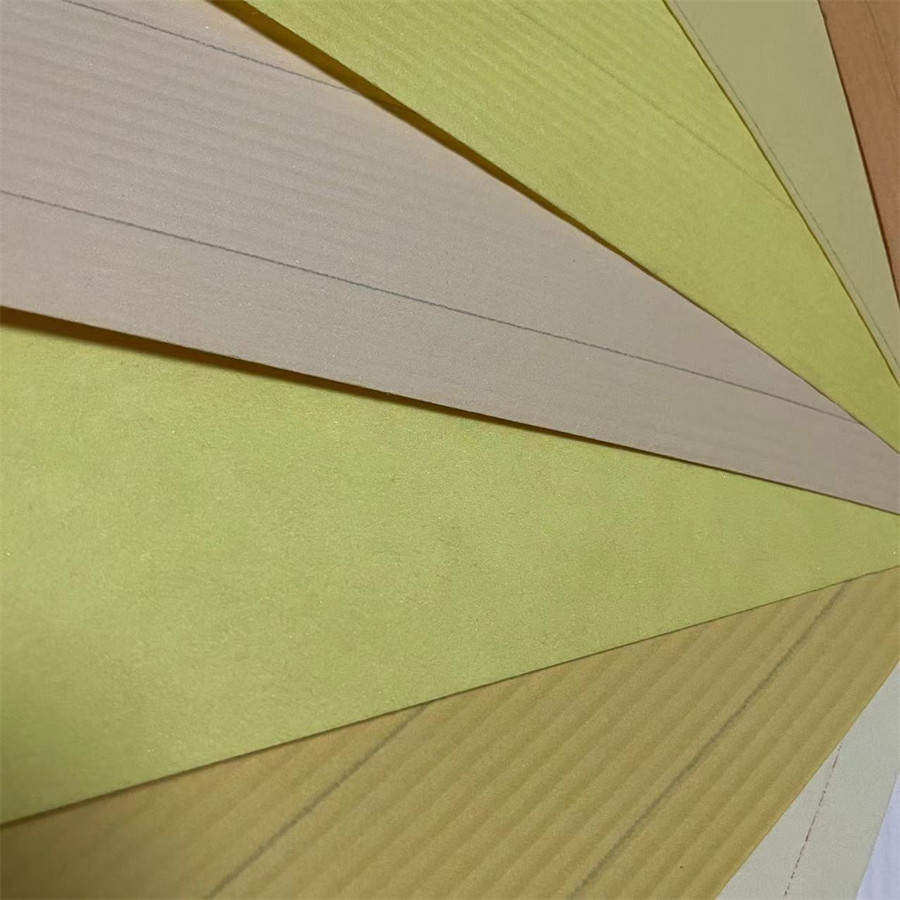

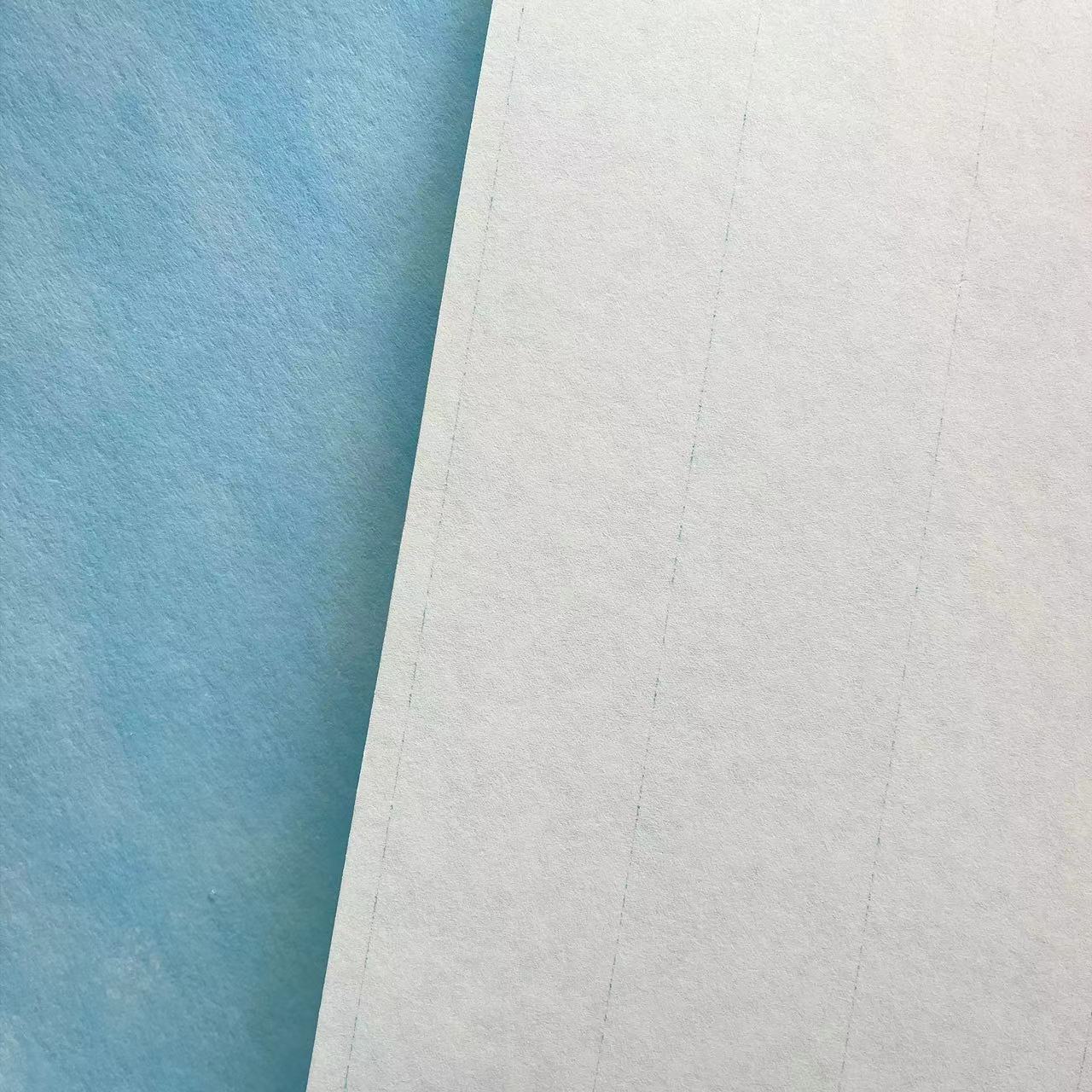

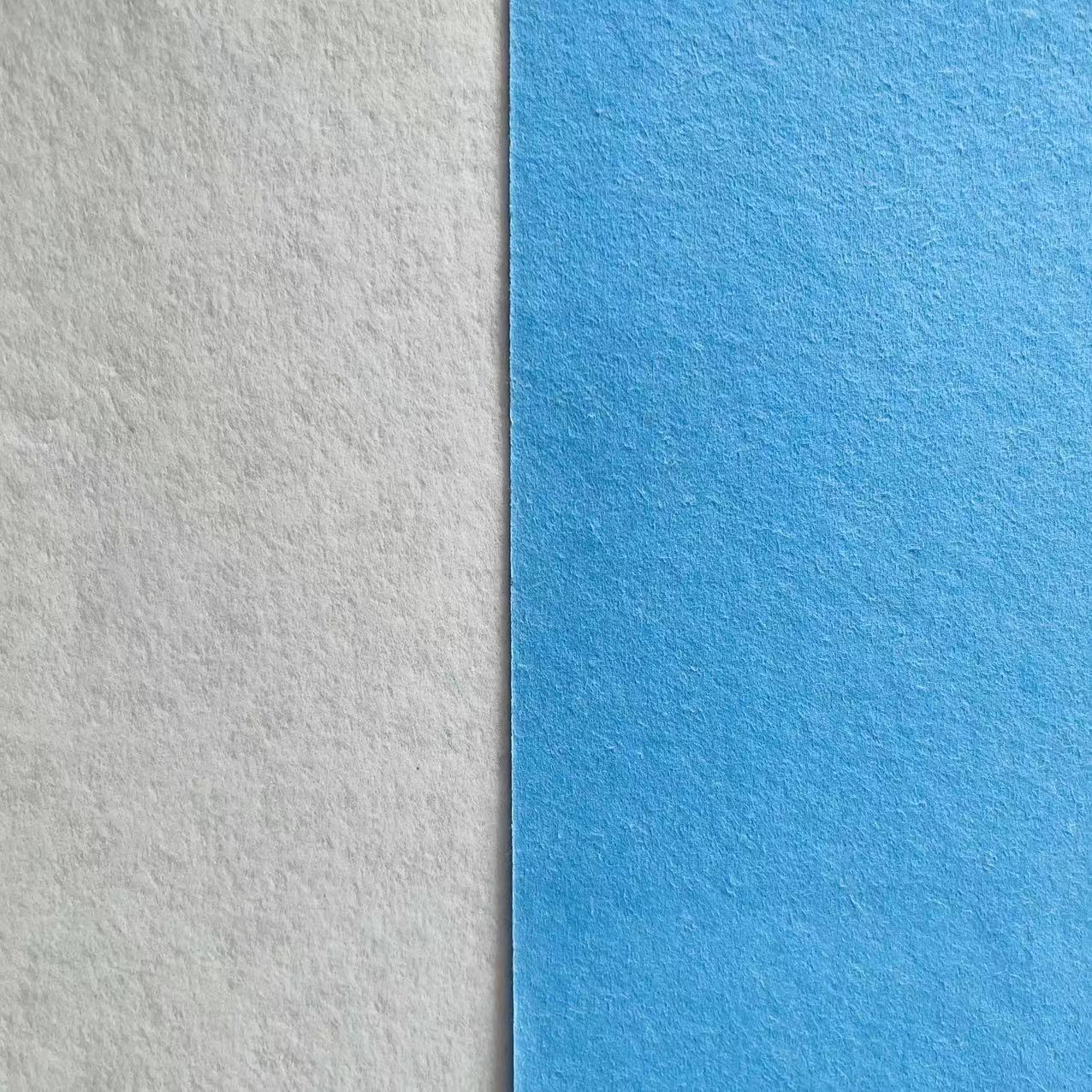

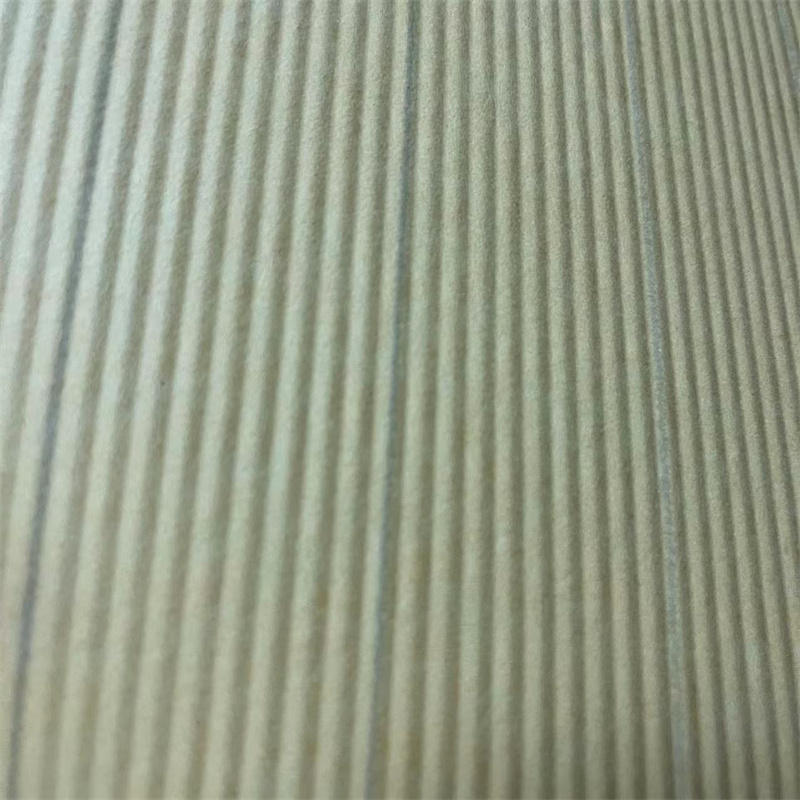

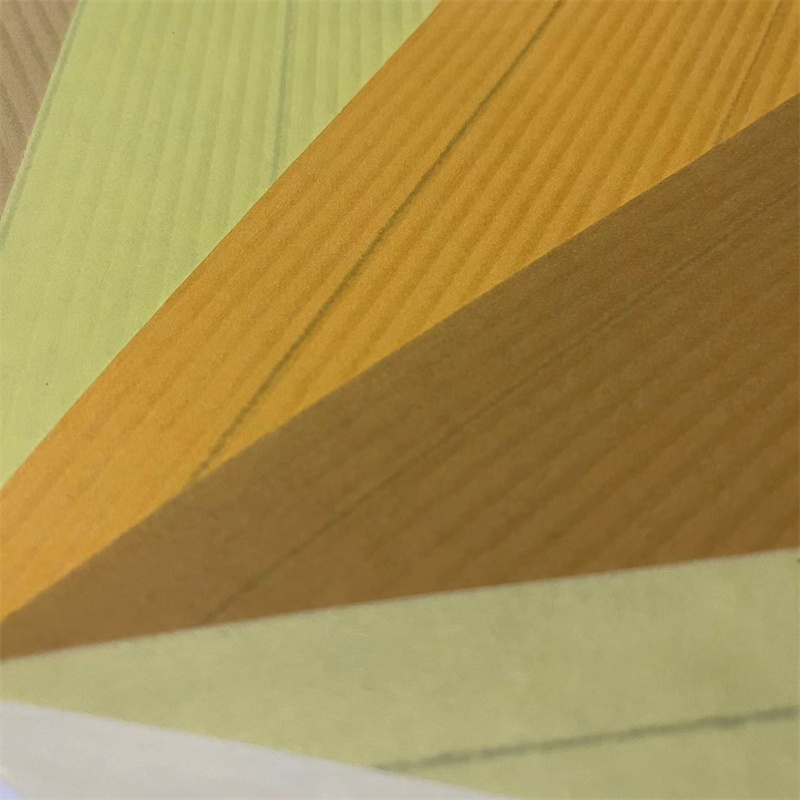

cured/phenolic filter paper

Application

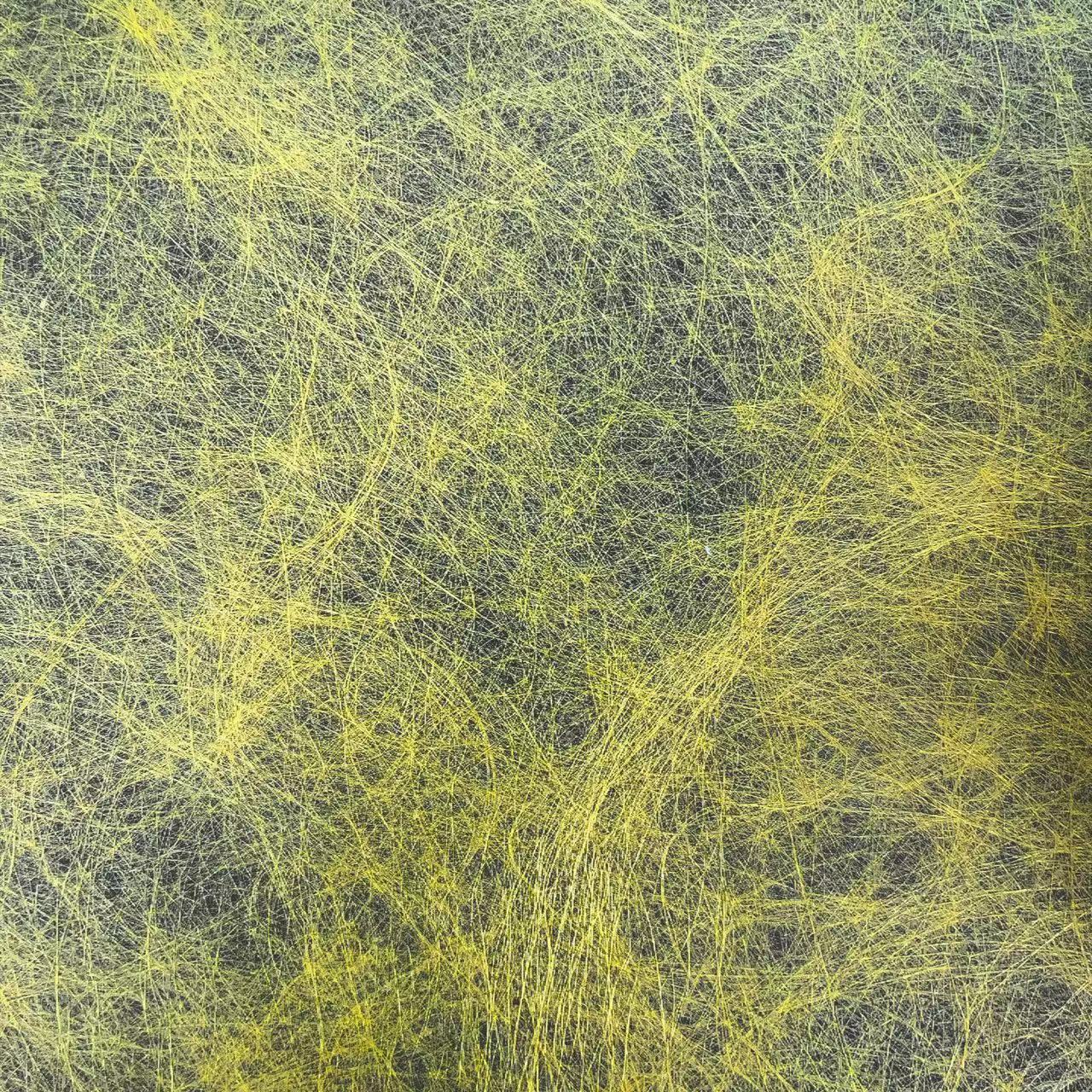

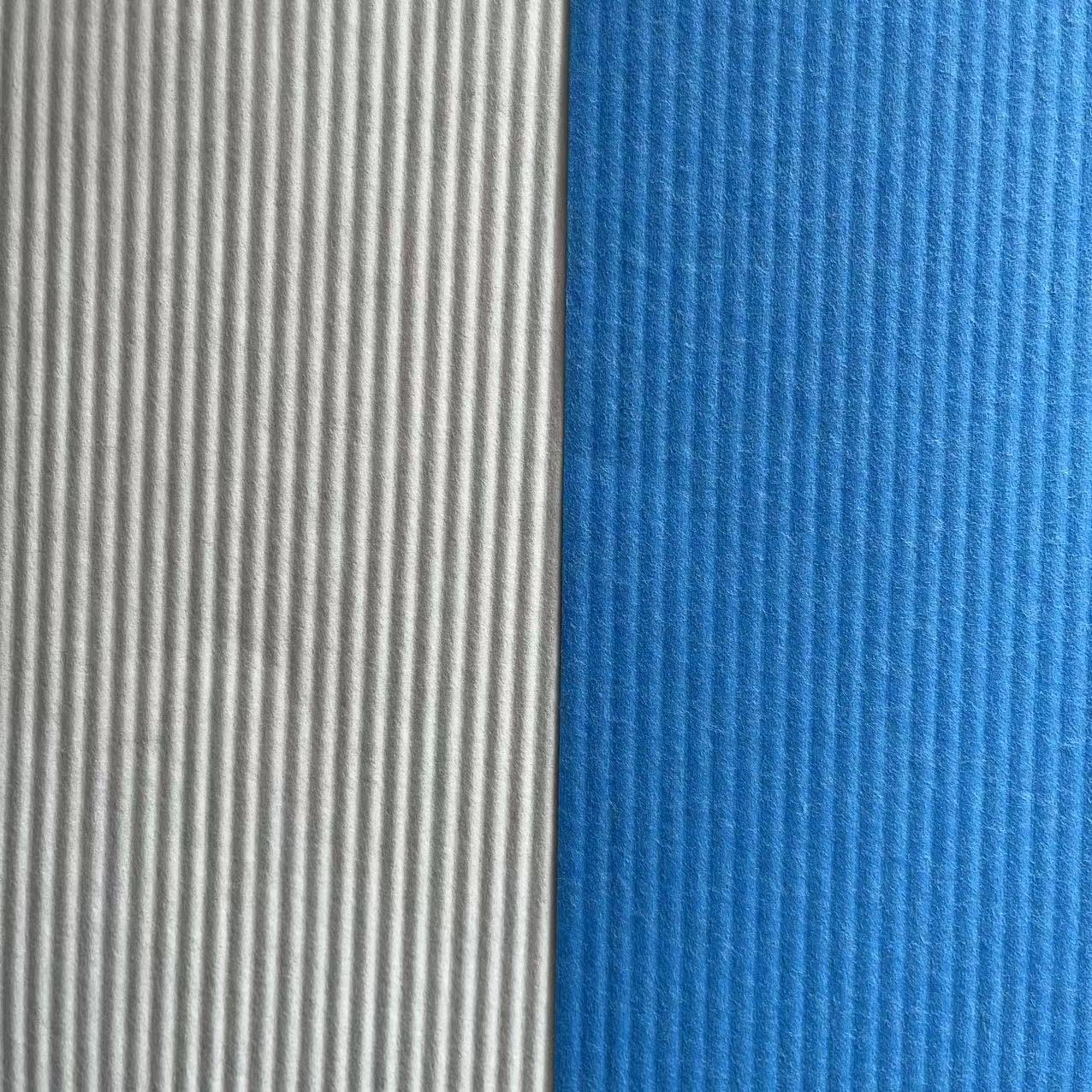

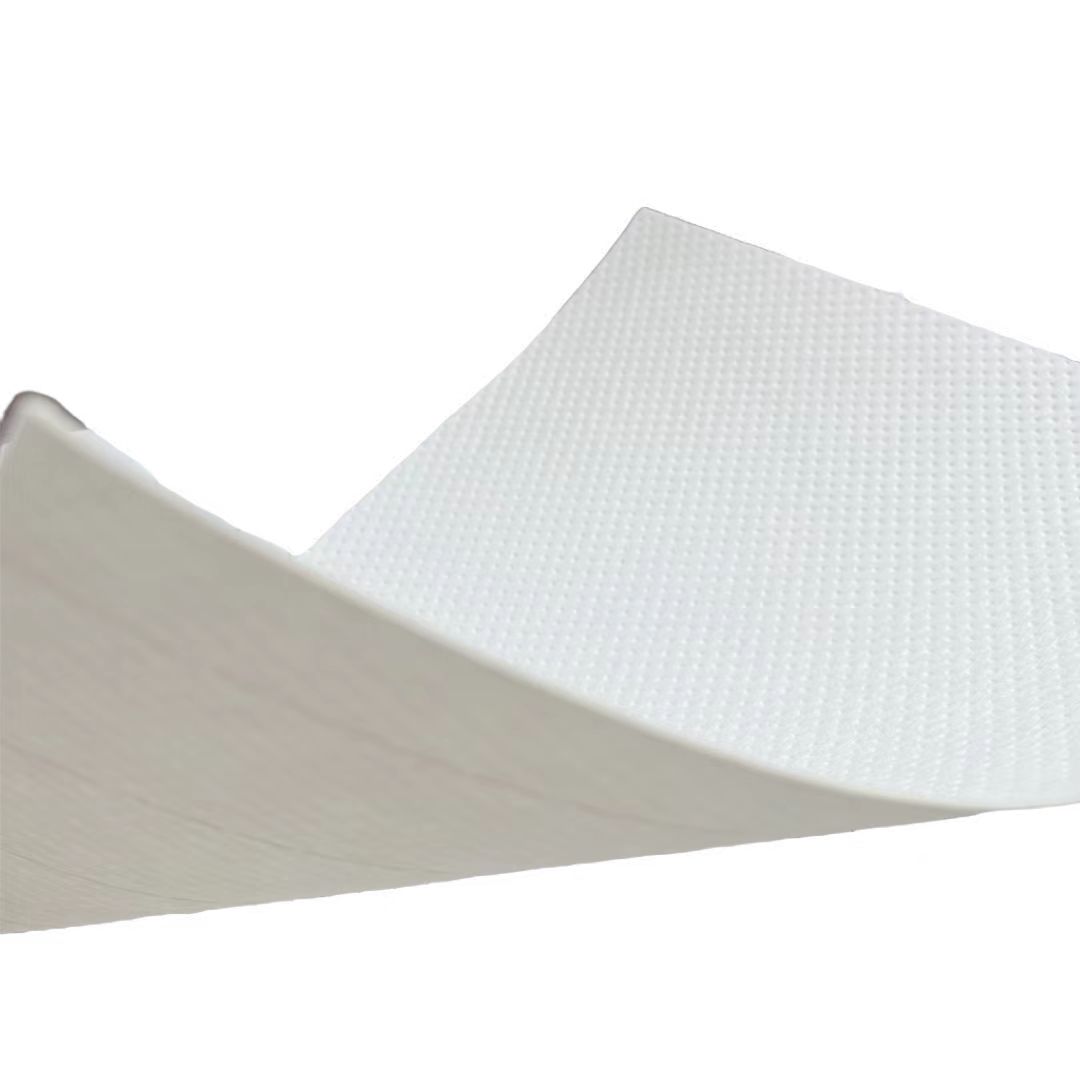

It is made of phenolic resin as the skeleton, combined with polyester fiber sintered at high temperature. Compared with ordinary organic fiber filter, phenolic resin filter has good stability, heat resistance and shrinkage performance, and can maintain high contaminant capacity. At the same time, viscous liquids such as coatings are easy to form embarrassing filtration resistance on the surface of the filter material during filtration, and the slotted design of the surface of the phenolic resin filter element can effectively increase the filtration area and the contaminant capacity of the filter element, which has a special effect on removing impurities and deformable particles in various colloids.

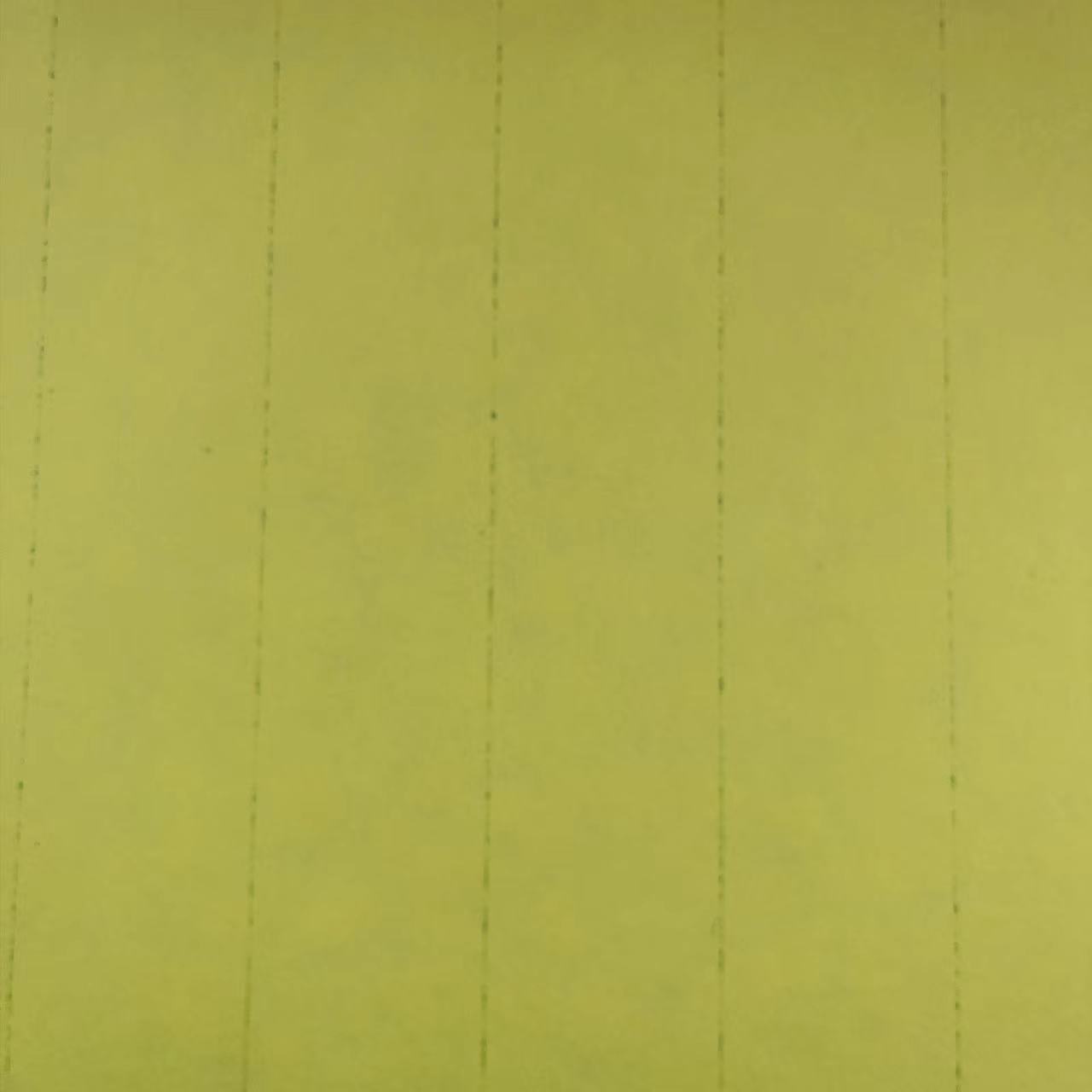

The rigid pore size distribution structure of the filter element can realize multistage filtration, which is especially suitable for the filtration of such high viscosity and high turbidity liquid. At the same time, the phenolic resin filter element has a long service life, which can effectively reduce consumption and reduce the input of manufacturers' costs.

Phenolic resin filter core is made of phenolic resin as skeleton, combined with polyester fiber sintered at high temperature. Compared with ordinary organic fiber filter core, phenolic resin filter core has good stability, heat resistance and shrinkage performance, and can maintain high contaminant capacity. At the same time, viscous liquids such as coatings are easy to form embarrassing filtration resistance on the surface of the filter material during filtration, and the slotted design of the surface of the phenolic resin filter element can effectively increase the filtration area and the contaminant capacity of the filter element, which has a special effect on removing impurities and deformable particles in various colloids. The rigid pore size distribution structure of the filter element can realize multistage filtration, which is especially suitable for the filtration of such high viscosity and high turbidity liquid. At the same time, the phenolic resin filter element has a long service life, which can effectively reduce consumption and reduce the input of manufacturers' costs.

more options