F8 engineering machinery filter paper

Application

F8 Medium effect filters are used as intermediate filters for ventilation and air conditioning systems in commercial and industrial cleanrooms, clean room air supply systems, automotive industry, hotels and office buildings.

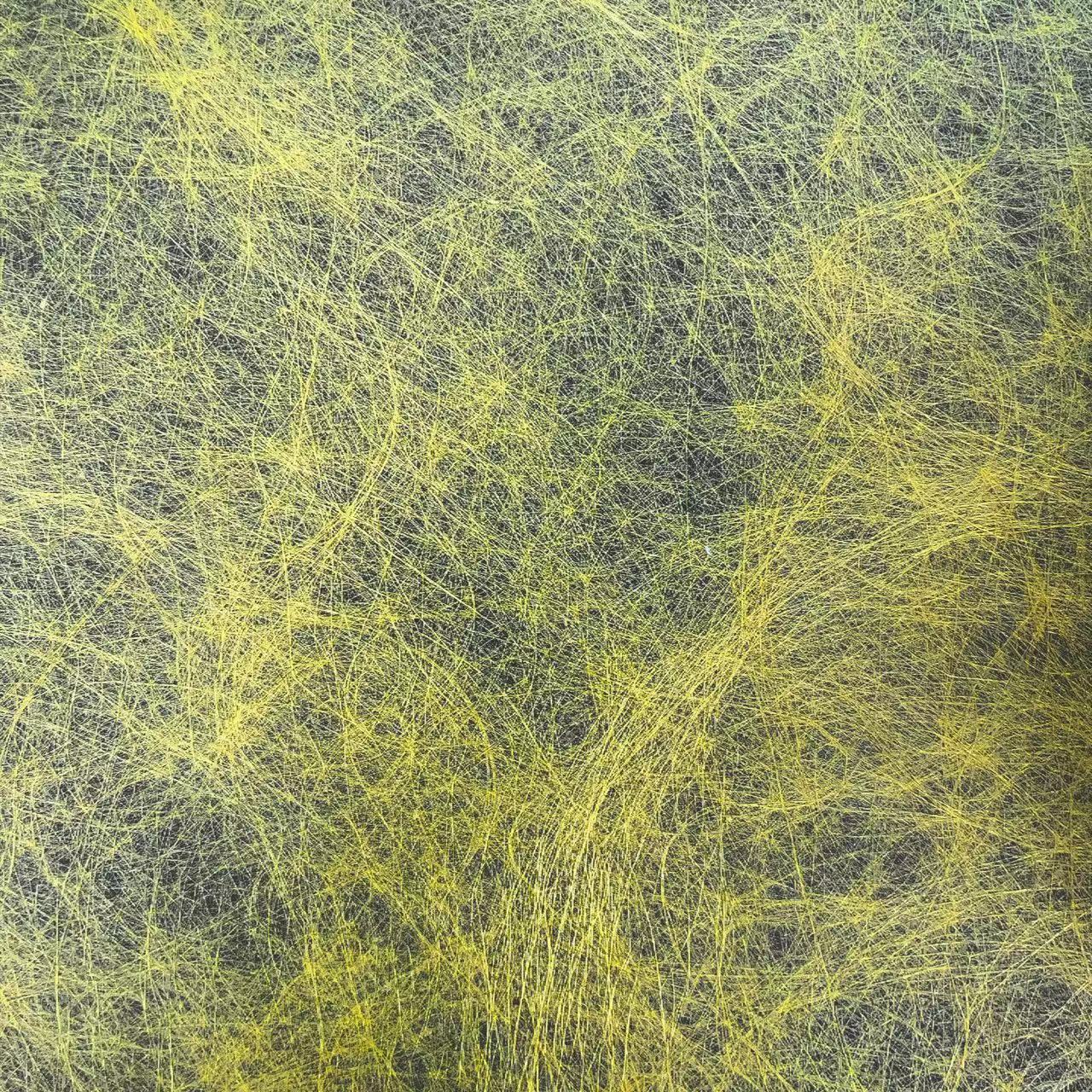

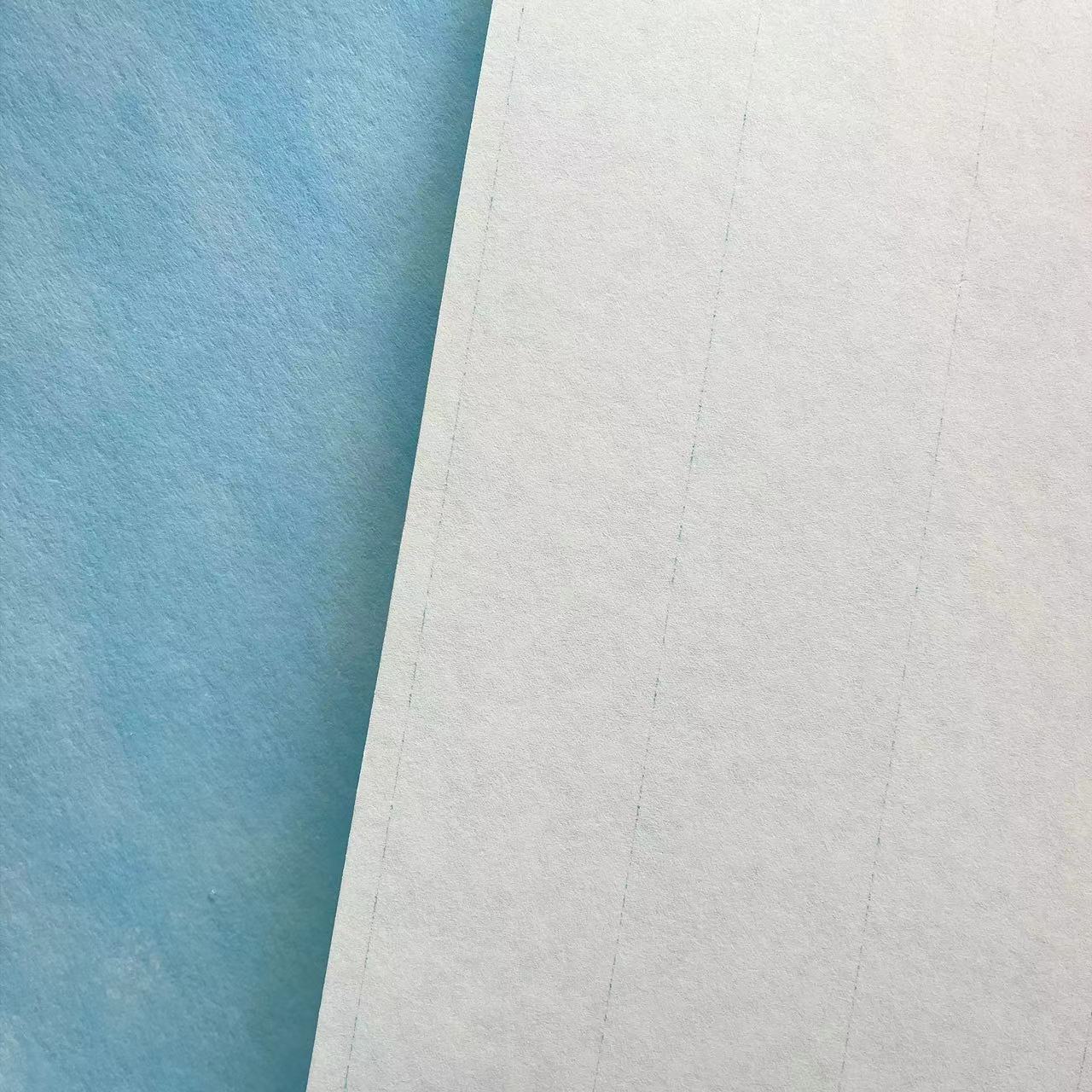

F8 medium effect filter generally uses non-woven fabric or imported glass fiber as filter material, the use of ultrafine chemical fiber filter material, large dust capacity, stable efficiency during the service cycle.

The existing air filter is made of plant fiber air filter material, and the application case investigation in the past 5 years has shown a large number of problems: 1. Plant fiber is a surface hydrophilic substance with a hollow structure. In the case of high humidity in hazy days, plant fiber absorbs moisture and expands, resulting in coarse fiber diameter, small porosity, reduced air permeability and significant increase in resistance. 2. The diameter of ordinary plant fiber is generally about 20μm, and the prepared air filter material is generally at the m5-m6 level, with low efficiency, and a large amount of dust enters the engine interior and post-treatment system, which will lead to a large area of engine wear and post-treatment blockage; 3. In the presence of wet and liquid pollutants, the hygroscopic plant fiber will not only swell, but also become longer, resulting in serious deformation of the filter core and serious internal folding, which seriously affects the service life; 4. Through the analysis of a large number of filter elements with short service life, the mixing of liquid pollutants and solid pollutants leads to the failure of the filter material is also one of the important reasons. The interaction of the two is adhered to the plant fiber like "paste mud", resulting in difficult dust difficult to blow down, the number of back blow cleaning is reduced, and the life is reduced.

Therefore, the current domestic air filter materials still stay in the traditional wood pulp fiber level, the product filtration efficiency is low, the resistance is large, the service life is short, and due to the upstream and downstream industry chain communication is not smooth, the lack of design means makes the product upgrade difficult. At the same time, foreign air filtration products, due to their design in accordance with European and American working conditions, show serious "acclimation" in China's severe haze environment, because of its technological blockade, the development of domestic advanced product production technology and technology is very slow. Therefore, in order to cope with the existing working conditions, an air filtration material with high efficiency and resistance to water vapor, acid, oil and other liquid pollutants is urgently needed, and the development of fully synthetic fiber air filtration materials is imminent.

Air Filter Paper For Engineering Machinery

Model number: LWK-115-130ENM

| Acrylic resin impregnation | ||

| Specification | unit | value |

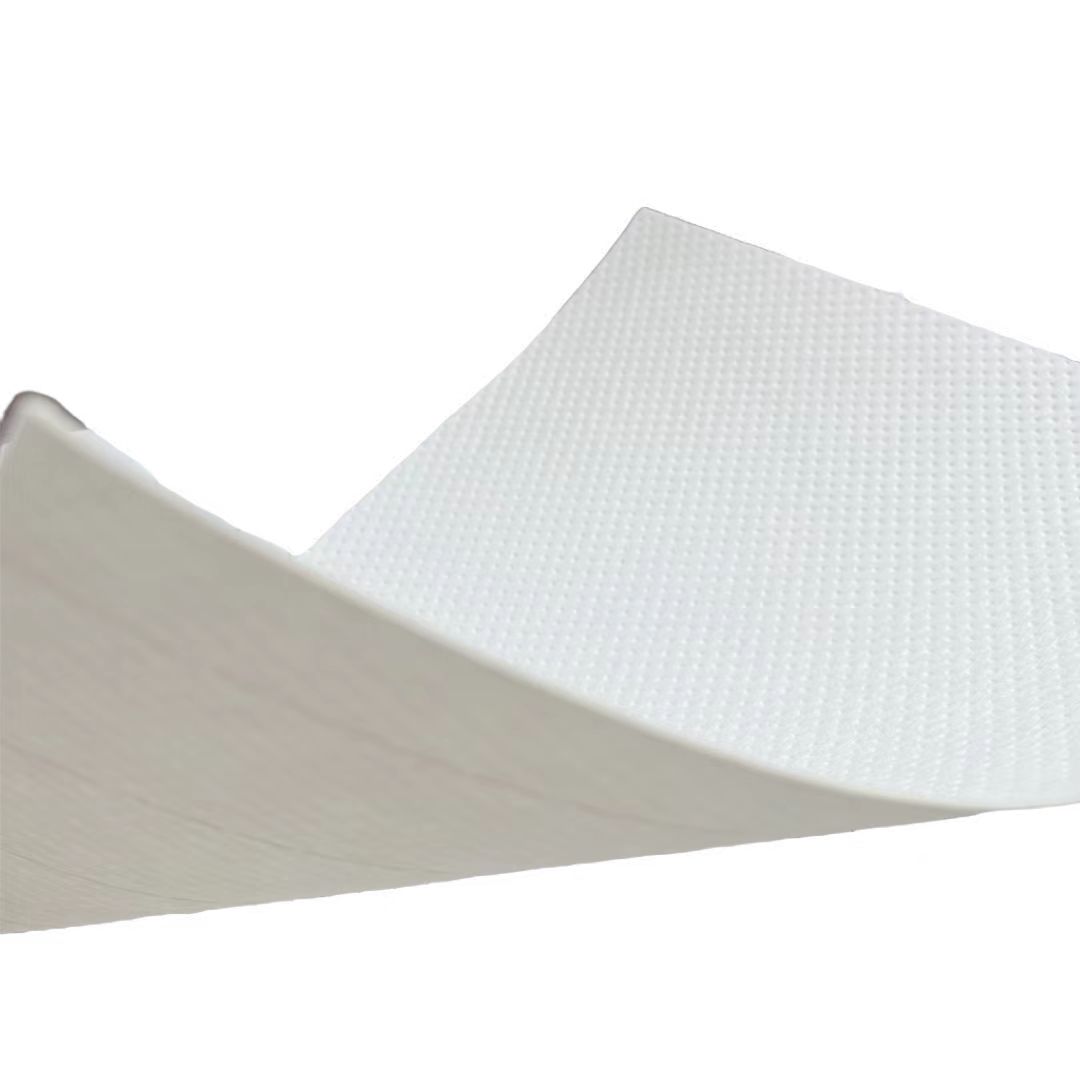

| Grammage | g/m² | 115±5 |

| Thickness | mm | 0.68±0.03 |

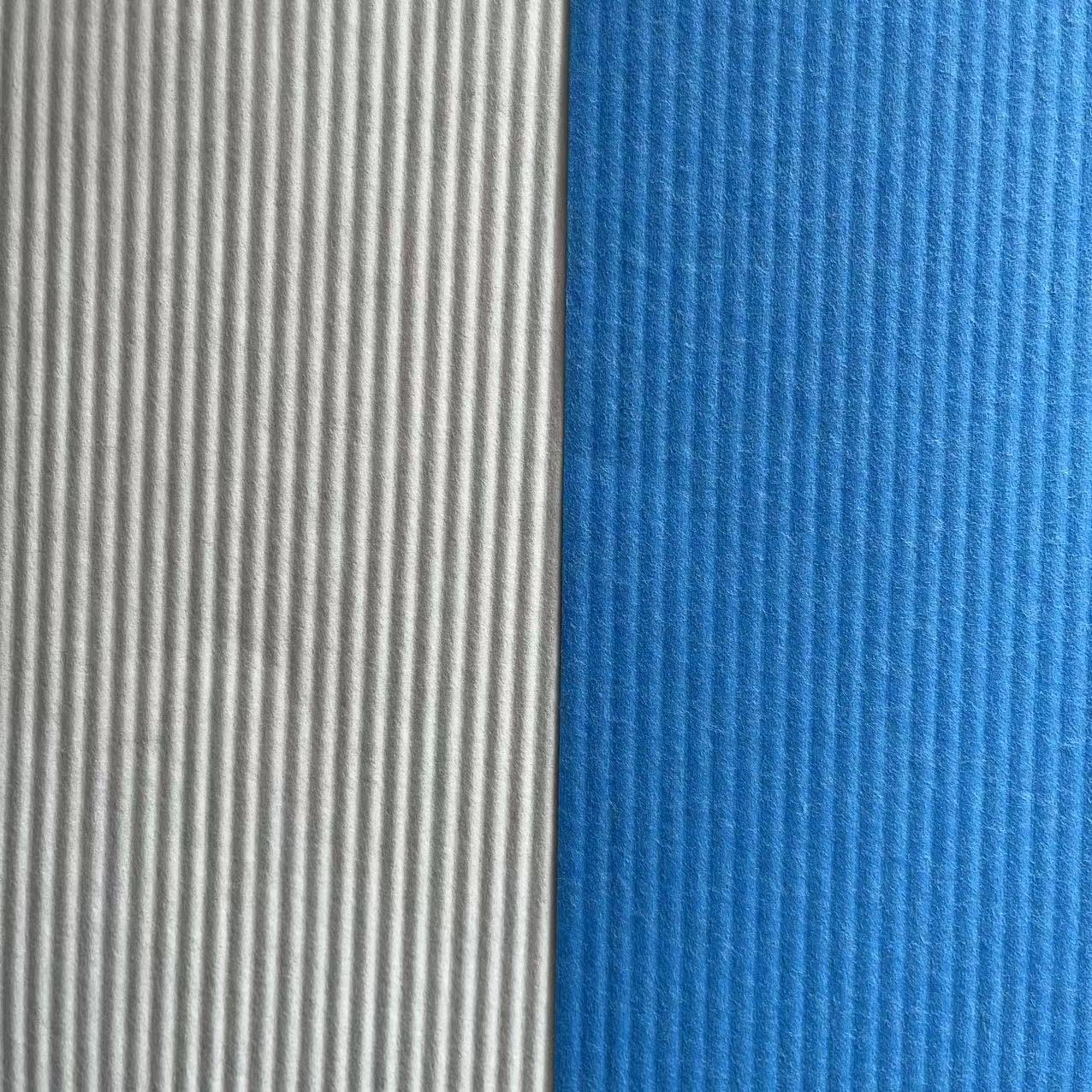

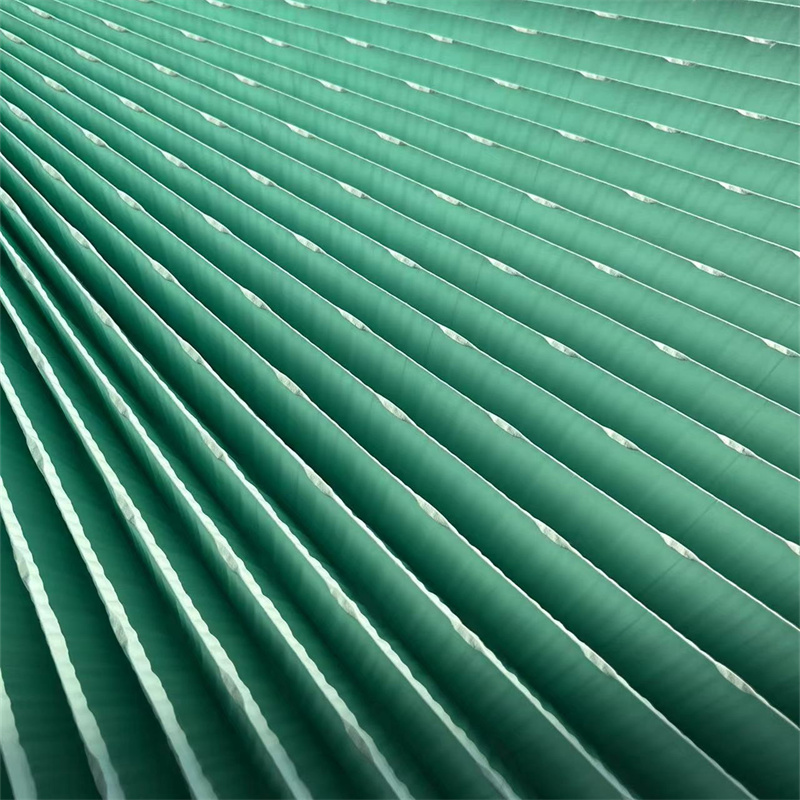

| Corrugation depth | mm | 0.45±0.05 |

| Air permeability | △p=200pa L/ m²*s | 130±20 |

| Max pore size | μm | 35±3 |

| Mean pore size | μm | 33±3 |

| Burst strength | kpa | 380±50 |

| Stiffness | mn*m | 7.0±0.5 |

| Resin content | % | 24±2 |

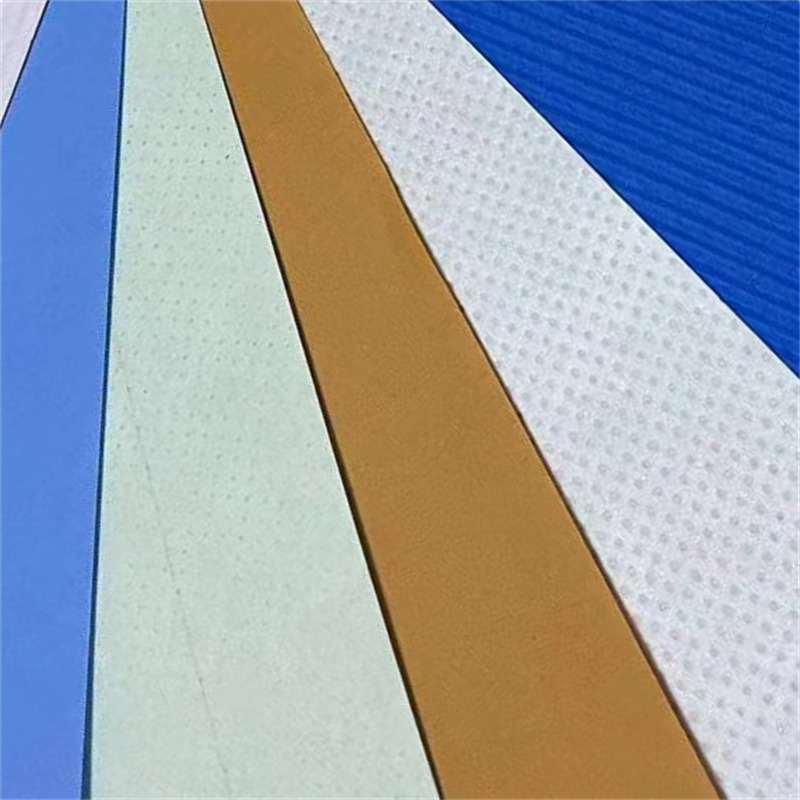

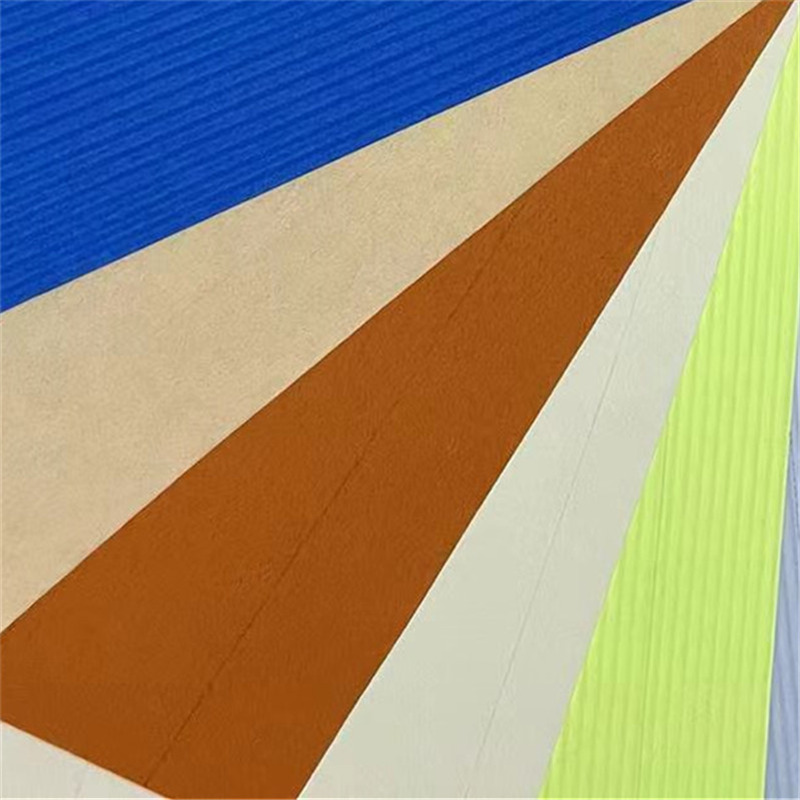

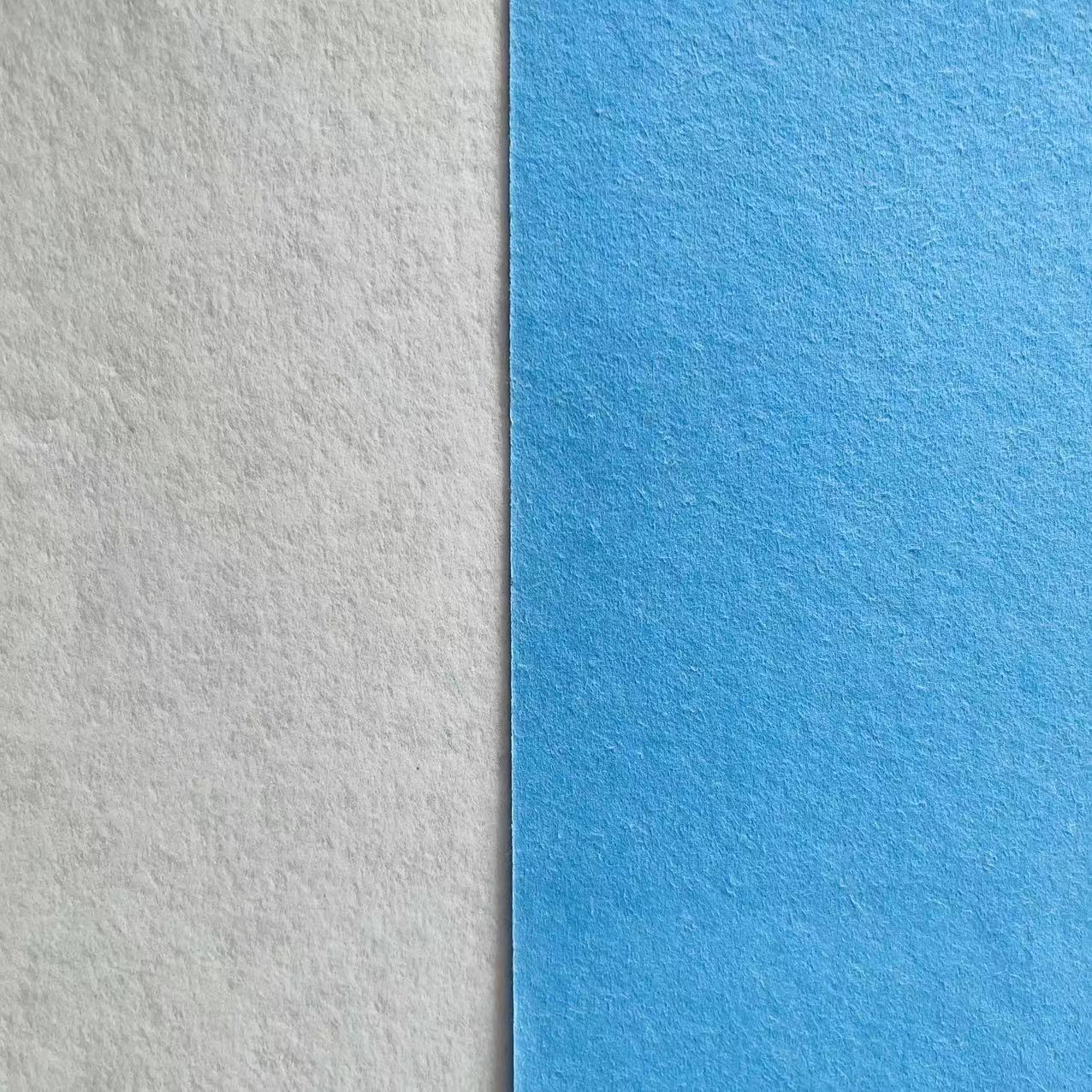

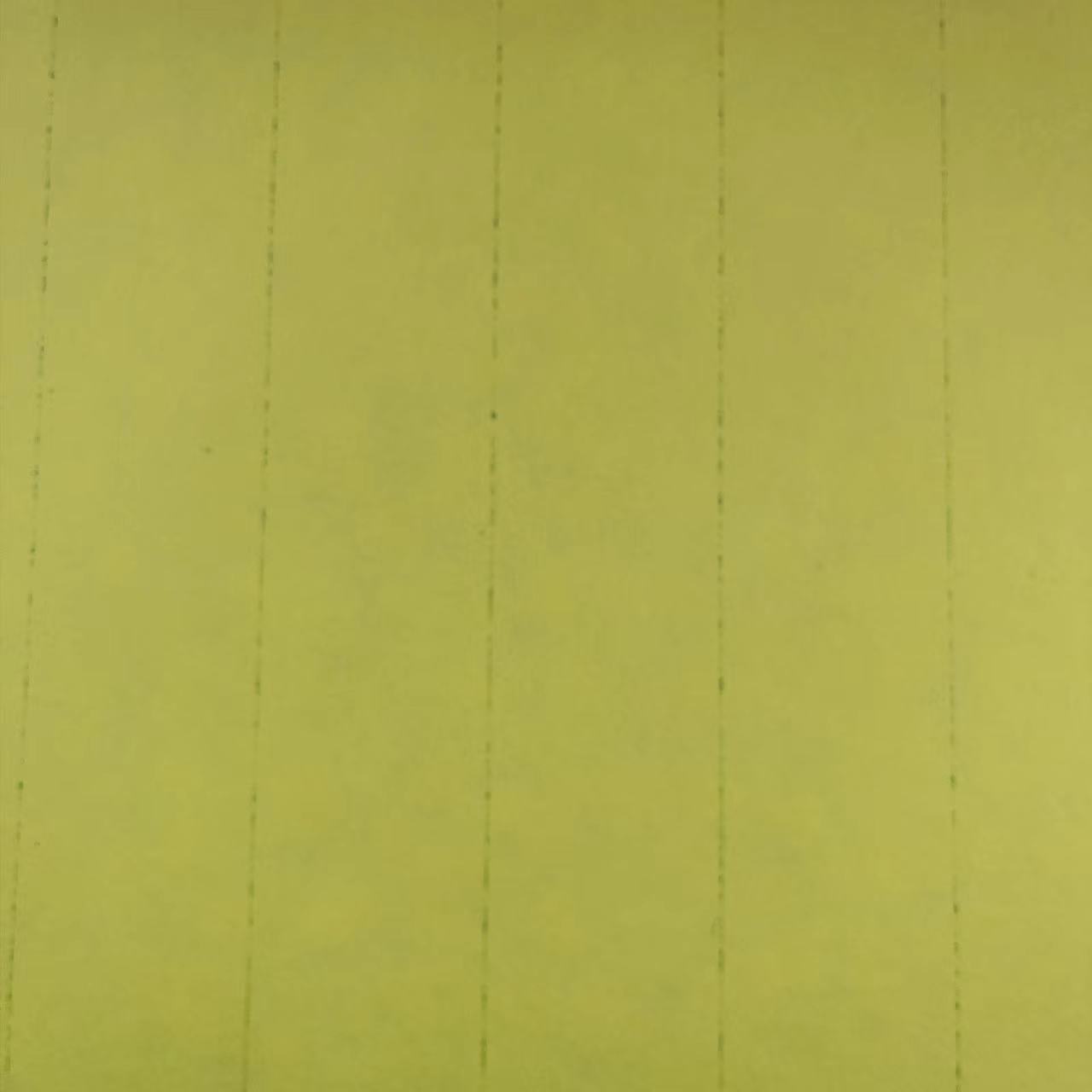

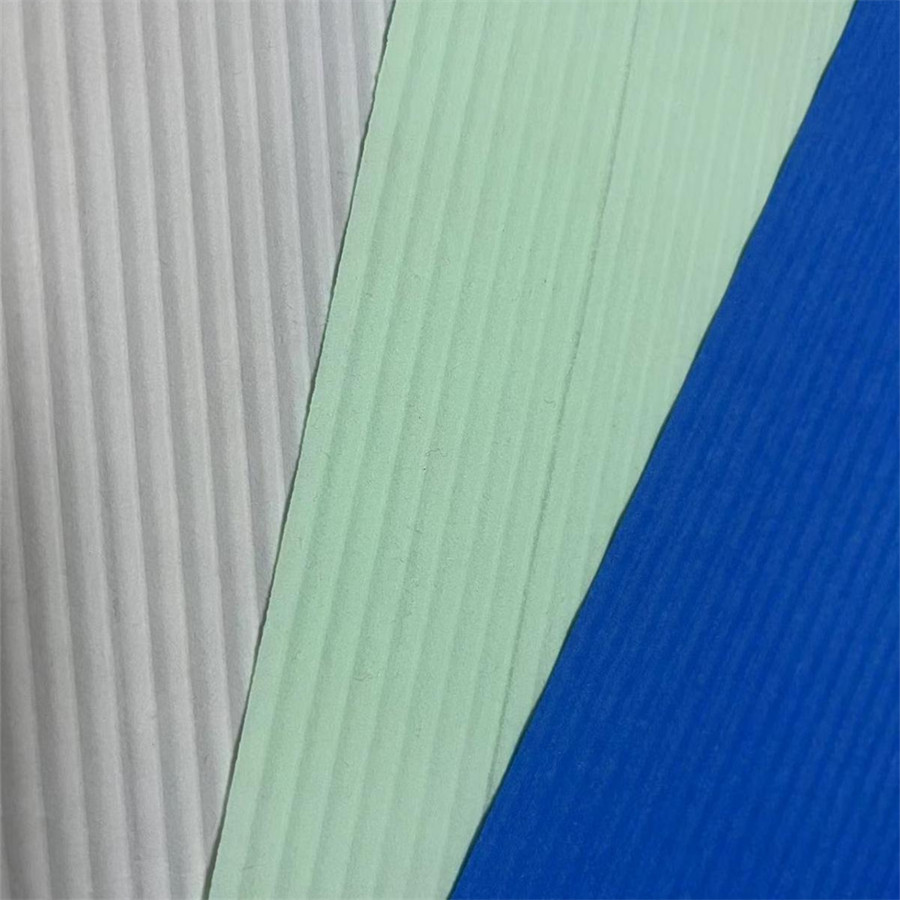

| Color | free | free |

| Note: color, size and each specification parameter can be changed as per customer’s requirement. | ||

more options