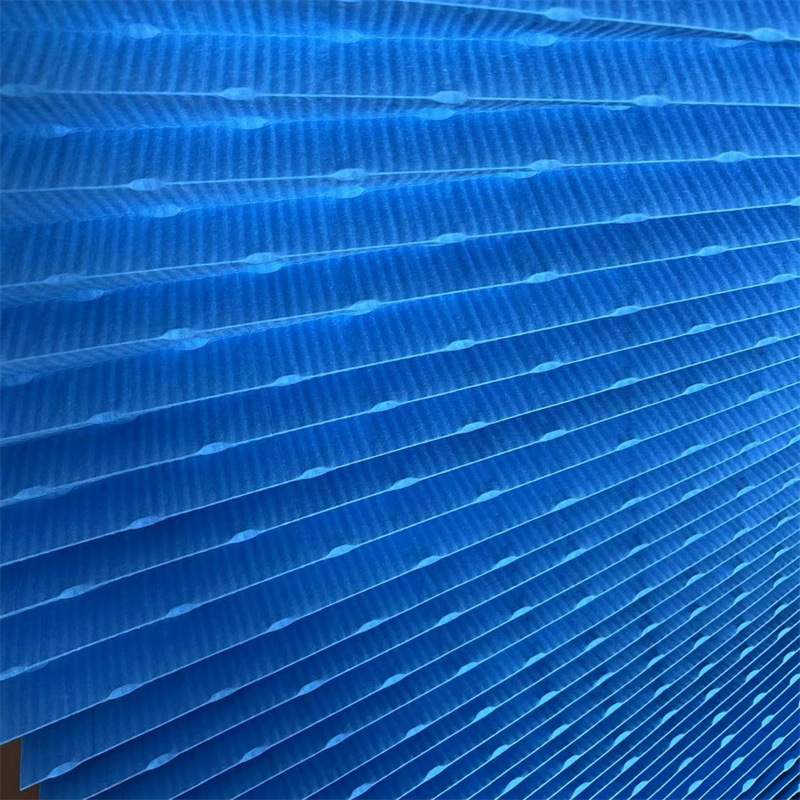

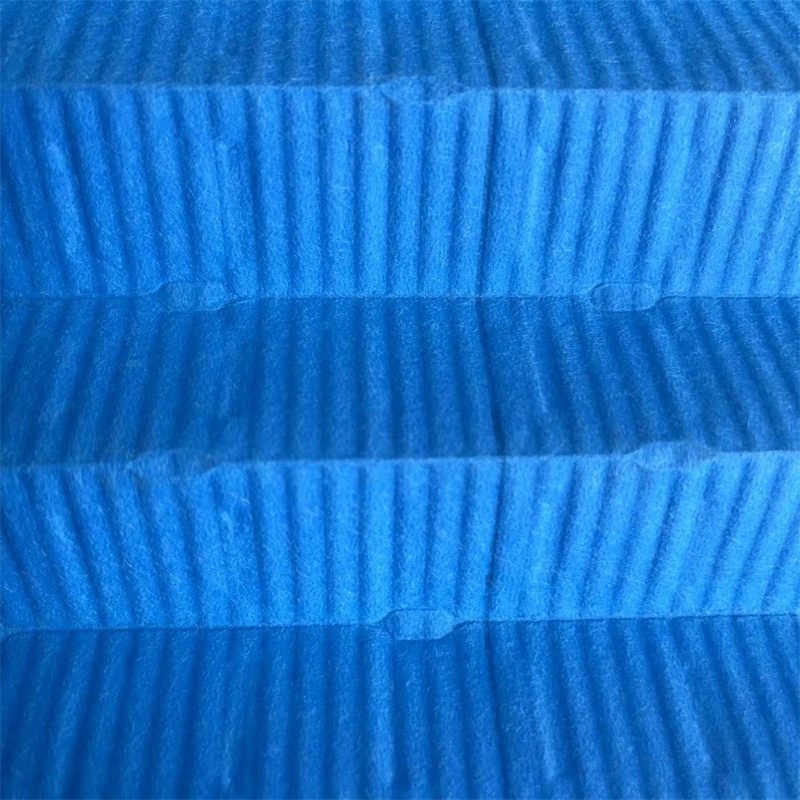

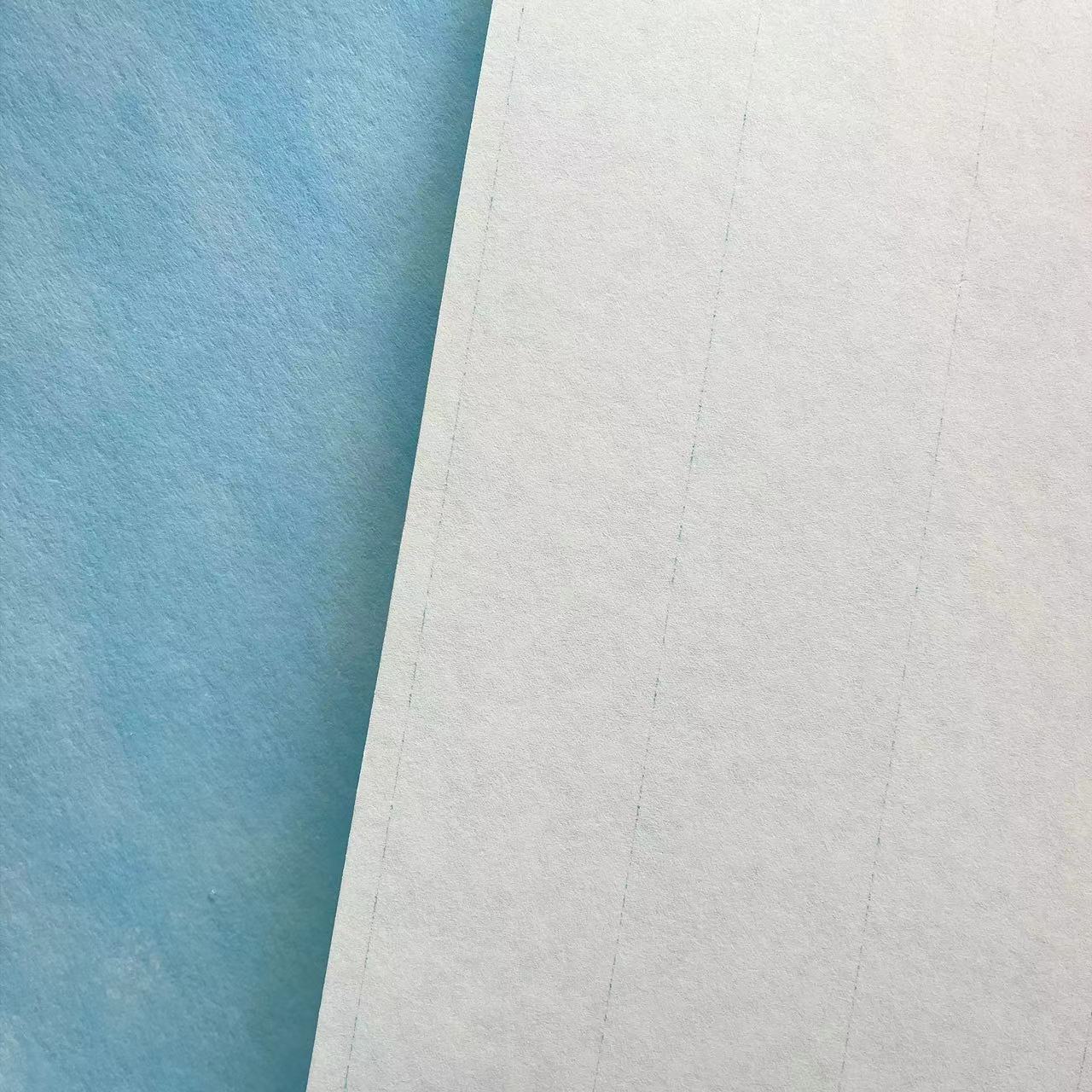

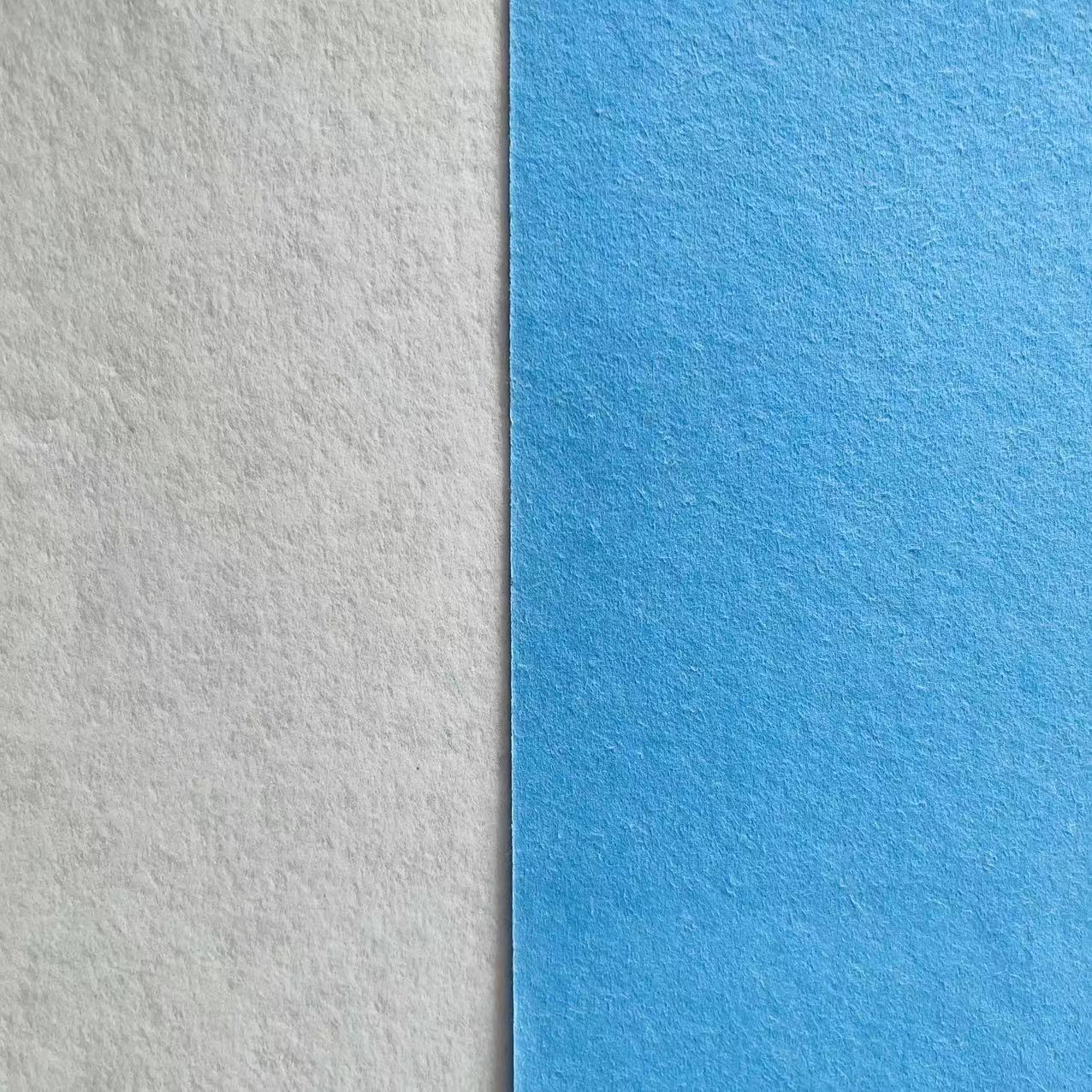

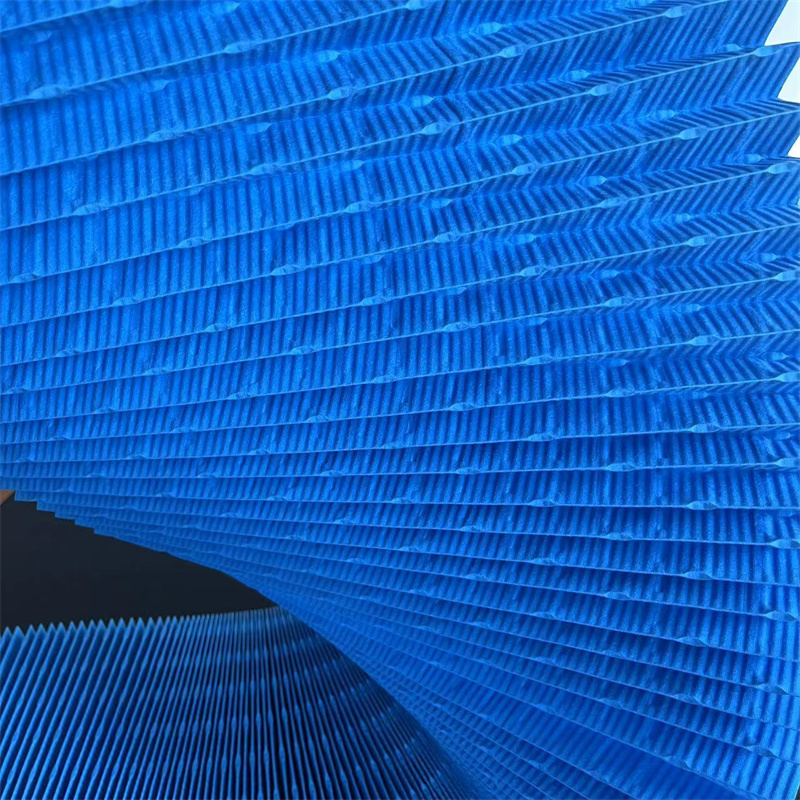

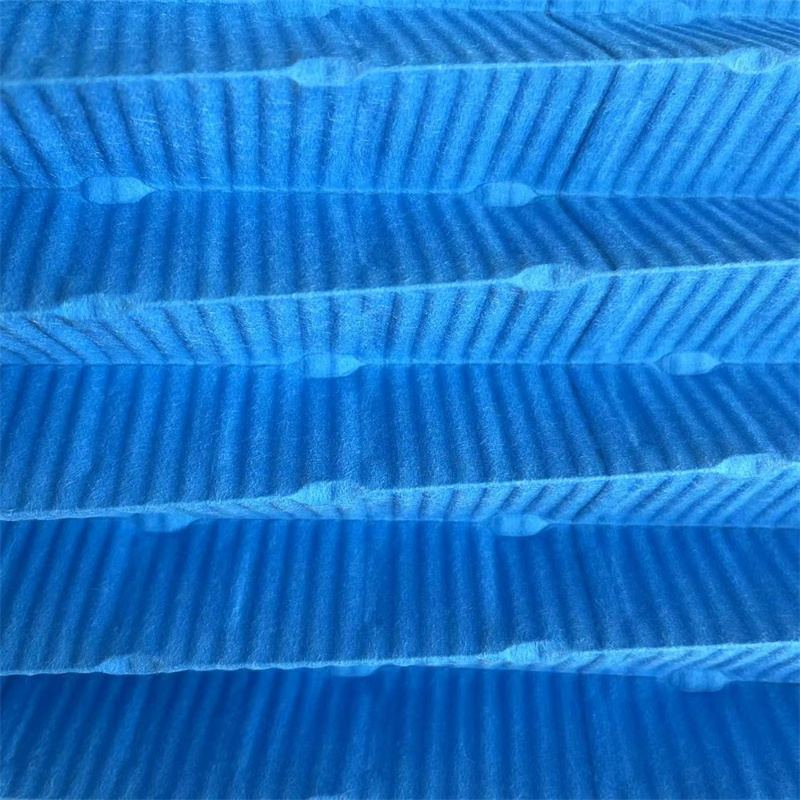

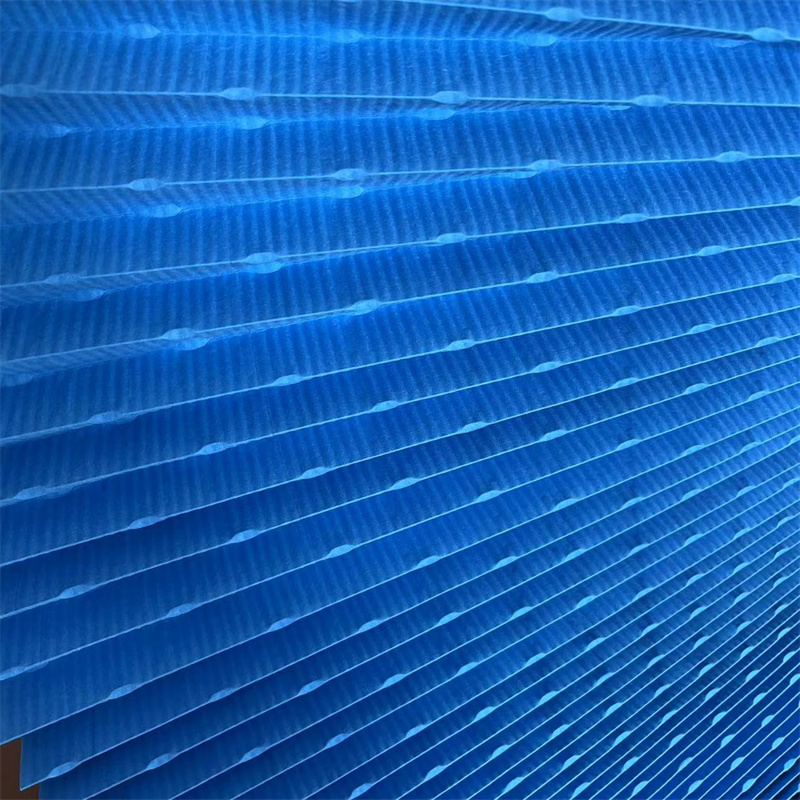

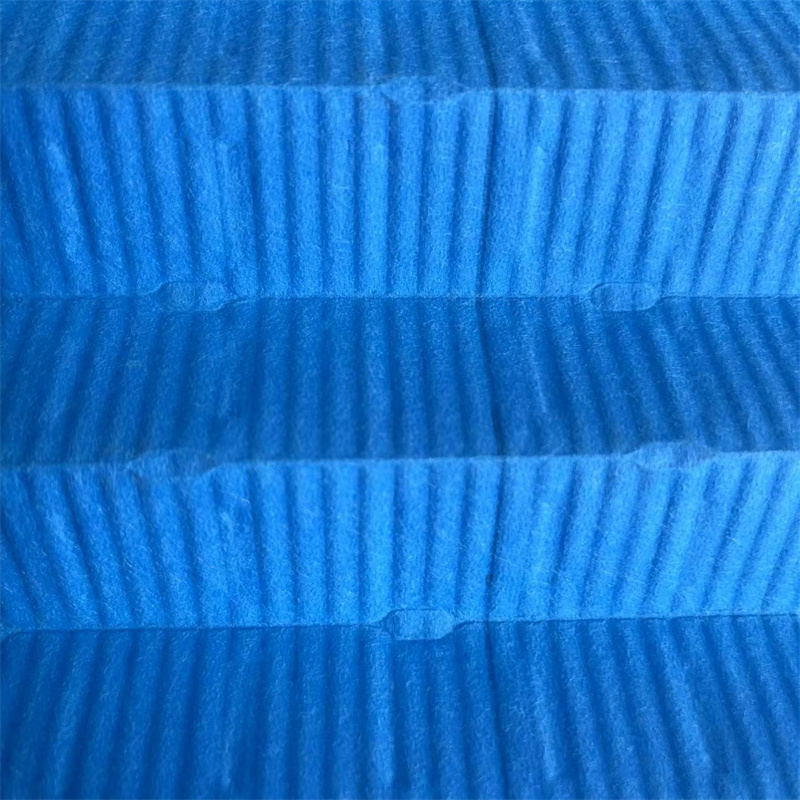

Nano fiber air filter paper

Application

1. polytetrafluoroethylene (PTFE)

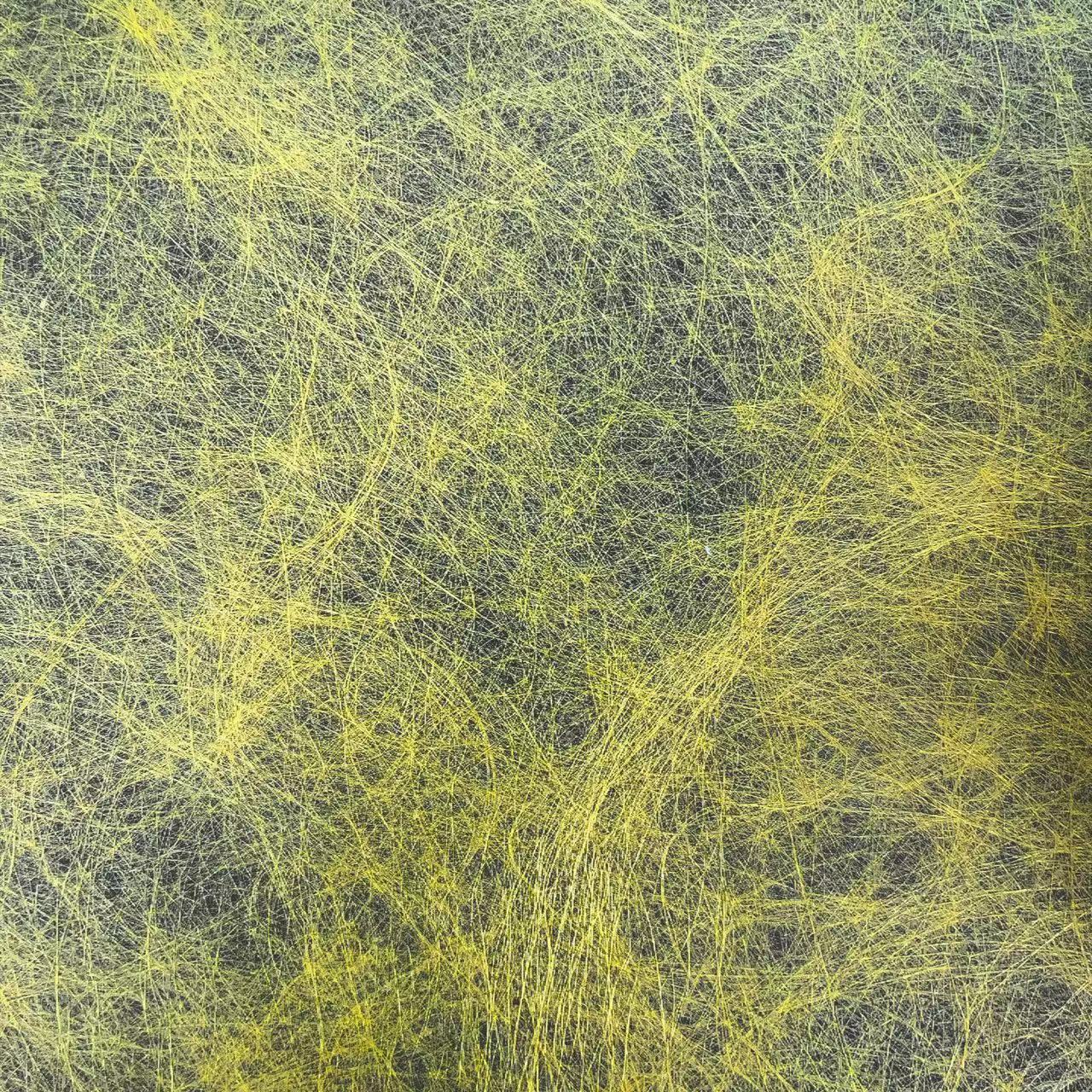

Polytetrafluoroethylene (PTFE) is a kind of high polymer without polar functional group, which has excellent chemical inertia and temperature resistance. It has certain stability and corrosion resistance, and can be used to manufacture efficient dust filter materials. In addition, the fiber structure of polytetrafluoroethylene is stable, the filtration efficiency is high, and the filter medium will not be damaged and have a negative impact on the environment. However, due to the relatively high cost of using polytetrafluoroethylene materials, its application in dust removal filters needs to be further optimized.

2. Polyethylene (PE)

Polyethylene is a commonly used polymer with good mechanical strength and chemical resistance. Polyethylene fiber can be used as a dust filter material, in the filter material can provide good filtration performance, but because of the poor high temperature resistance of the material, it is usually added to the surface of the material special treatment to improve the temperature resistance. Compared with polytetrafluoroethylene, polyethylene material has a lower cost, so it has gradually become one of the main materials of dust removal filter.

3. Polyimide (PI)

Polyimide is a polymer material with excellent high temperature resistance and chemical resistance. Its high temperature resistance and high chemical resistance make it widely used in dust removal filter materials. In high temperature environment, the fiber formation structure of polyimide nanofibers can be better maintained, thus improving the filtration efficiency of the filter material. In addition, the polyimide material has excellent friction resistance and antistatic properties, which can effectively prevent the accumulation of granulation in the filter medium, thus extending the service life of the filter.

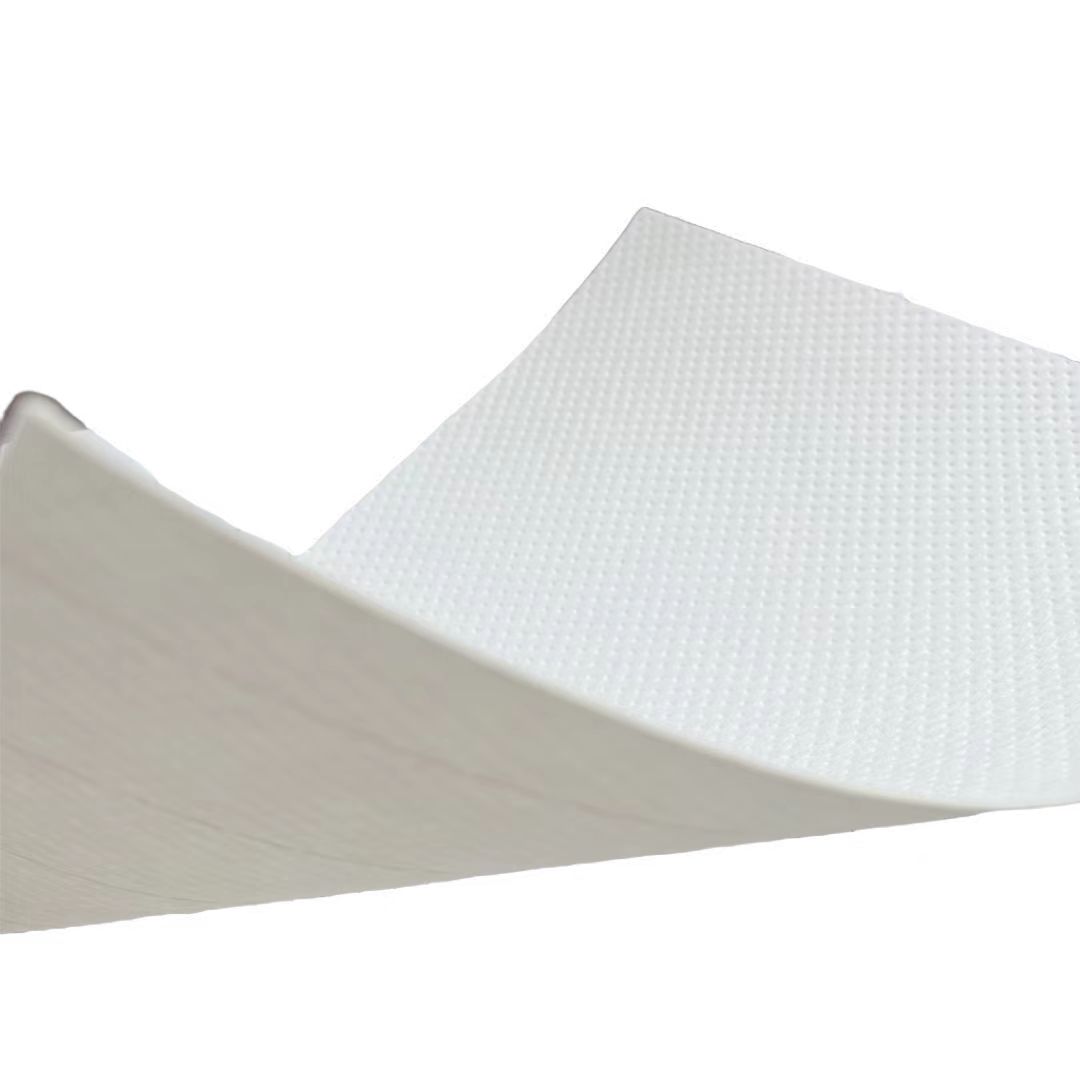

Air Filter Paper For Heavy-Duty Nano

Model number: LPK-140-300NA

| Acrylic resin impregnation | ||

| Specification | unit | value |

| Grammage | g/m² | 140±5 |

| Thickness | mm | 0.55±0.03 |

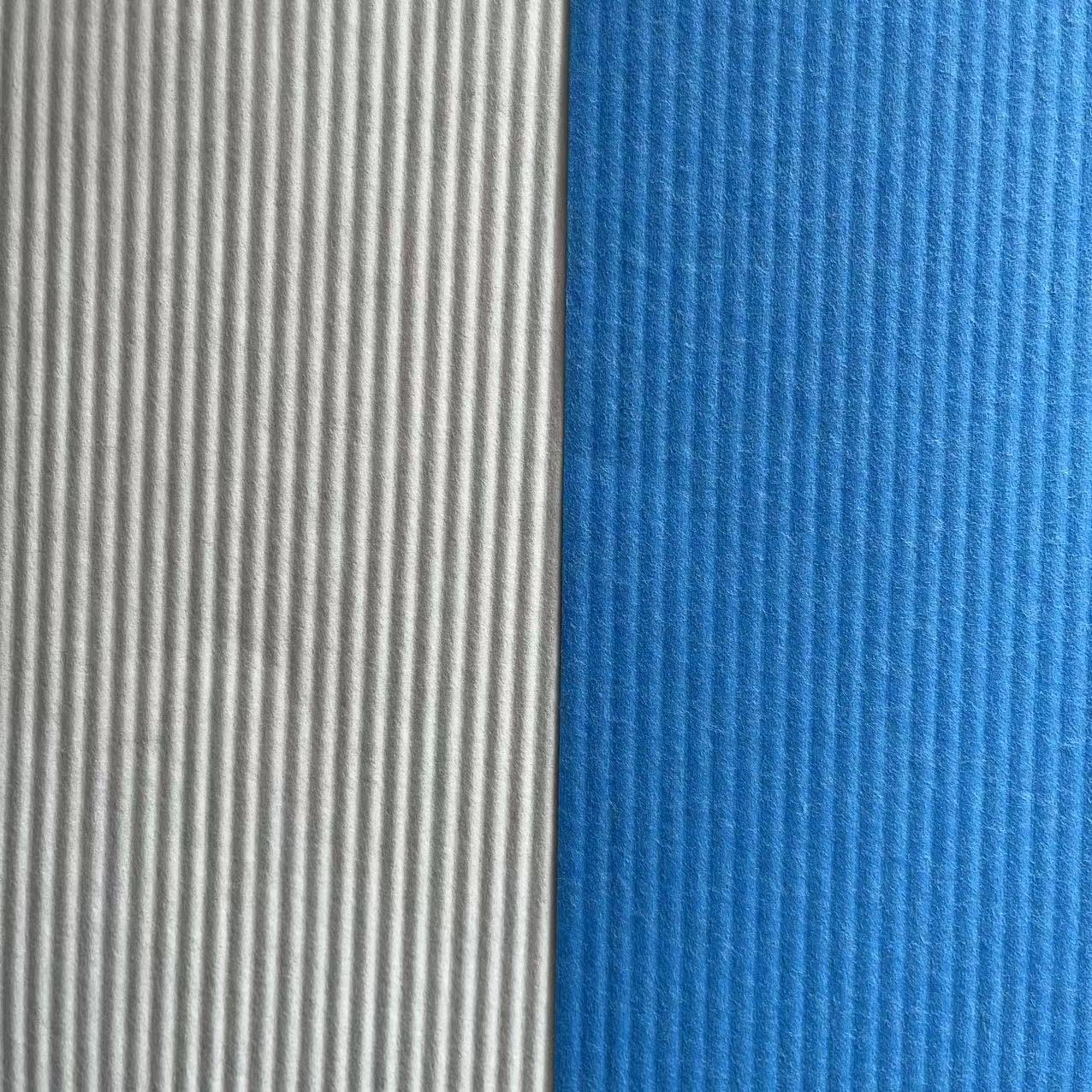

| Corrugation depth | mm | plain |

| Air permeability | △p=200pa L/ m²*s | 300±50 |

| Max pore size | μm | 43±5 |

| Mean pore size | μm | 42±5 |

| Burst strength | kpa | 300±50 |

| Stiffness | mn*m | 6.5±0.5 |

| Resin content | % | 23±2 |

| Color | free | free |

| Note: color, size and each specification parameter can be changed as per customer’s requirement. | ||

Application prospect

The application prospect of nano-fiber materials is very broad, especially in dust removal filter material. In the future, nanofiber materials can further improve the cost effectiveness of their preparation and the diversity of application fields, so as to provide better dust removal filter products for modern industrial production. At the same time, the application of nanofiber materials still faces some challenges, such as the preparation conditions of the materials are not easy to control, and the processing technology is complex. Therefore, in the future, it is necessary to continuously strengthen research and improve the production process of nanofiber materials to promote their further application in the field of dust removal filter materials.