Automotive filter paper is one of the main materials for the production of automotive filters, that is, air filter paper, oil filter paper, fuel filter paper

Steam filter, the full name of gasoline filter, is a kind of fuel filter, is to filter fuel impurities, provide clean fuel for the engine, protect the engine and the important auto parts of the oil supply system. In the process of production, storage and use of gasoline, it is inevitable to produce certain impurities such as iron oxide, dust, etc., or some oil station oil quality itself is poor, containing a large number of impurities, if you do not filter out these impurities, bring it into the engine and oil supply system, it is possible to damage the cylinder or cause fuel nozzle blockage. This requires steam filtration to filter impurities and ensure the normal operation of the vehicle.

Filter paper, sometimes referred to as filter paper, is a special filter medium material. If more specifically subdivided, it contains: general chemical analysis filter paper, "three clear" (clean air, fuel oil, lubricating oil) filter paper, oil filter paper, beer filter paper, high temperature filter paper, and so on.

From the structure of paper, it is the use of fibers (plant fibers and a variety of other fibers) interwoven. The fibers are misaligned with each other to form many small holes, so they have good permeability to gases or liquids. Moreover, the thickness of the paper can be large or small, the shape is easy to process, and the folding and cutting are convenient. At the same time, in terms of production costs, transportation and preservation, the cost is relatively less.

What role can filter paper play? To put it simply, it can be used for separation, purification, concentration, decolorization, deodorization, recycling, etc. This is very meaningful for environmental protection, human health, equipment maintenance, saving resources and so on.

Raw materials used in filter paper, some are all plant fibers (chemical wood pulp, cotton pulp, mulberry bark pulp, etc.), such as chemical analysis filter paper; Some are glass fiber, synthetic fiber, aluminum silicate fiber; Some use plant fibers and add some other fibers, even including metal fibers. In addition to the above mixed fibers, some fillers should be added according to the formula, such as titanium bai powder, perlite, activated carbon, diatomaceous earth, wet strength agents, ion exchange resins, etc.

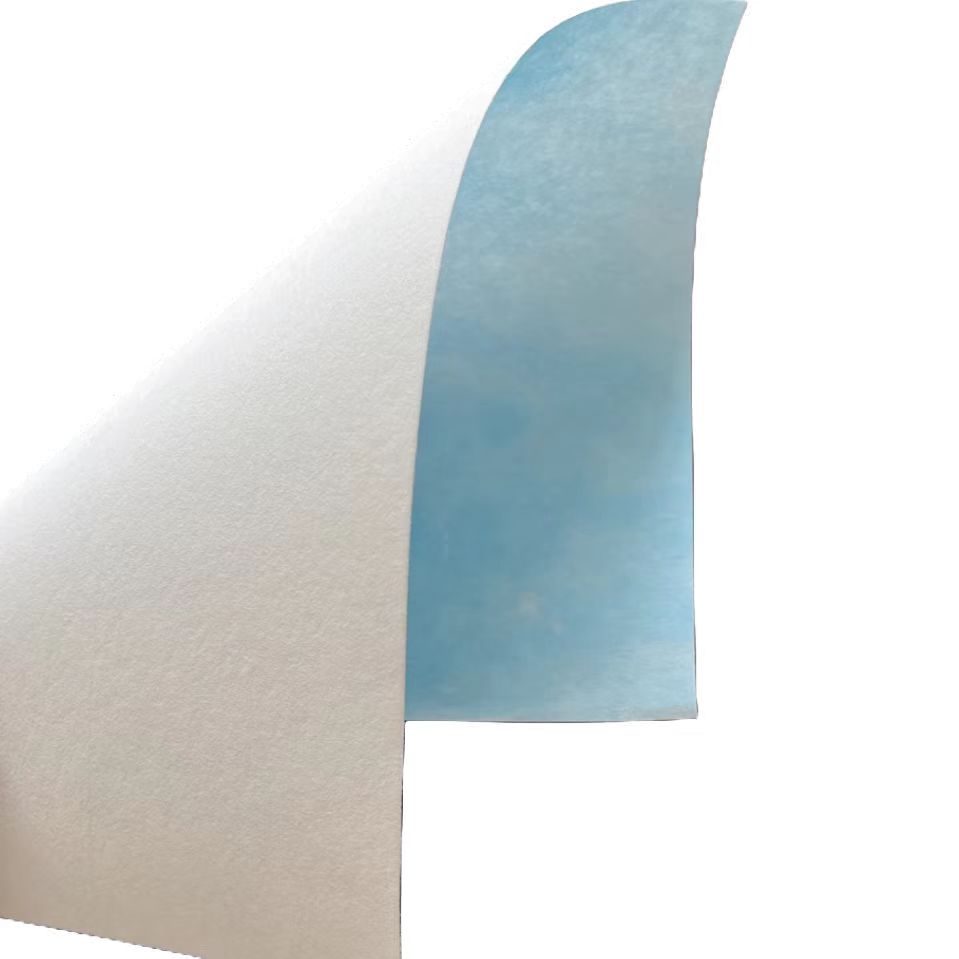

After a series of process treatment, the paper pulled out of the paper machine is processed again as needed: it can be sprayed, it can also be impregnated, and it can also be lined with other materials (such as non-woven fabrics, etc.).

Since the production of filter paper is more raw materials, the variety of products, and the requirements for its performance are different, it is necessary to specify various performance indicators to judge the quality of the filter paper or determine whether it can meet the requirements of use. In general, the filter paper needs to be strong enough to withstand the impact of the liquid or gas being filtered without any chemical interaction with it. In other words, the filter paper itself is chemically inert. If the filtered liquid is related to human health, the harmful substances and impurities contained in the filter paper must be controlled in line with health standards. In terms of measuring the permeability of filter paper, its air permeability, porosity, water filtration speed, filtration efficiency, ion exchange capacity, etc., depending on its specific application, there are corresponding regulations.