Filter paper secret in construction machinery!

Partial fault information

Most of the faulty engines have problems such as fuel injector leakage and black smoke from the engine. According to past experience, if the fuel quality is poor and not well filtered, impurities in the fuel often cause wear of the injector seat. In the long run, it will lead to leakage of the injector, and too much fuel will enter the cylinder, resulting in insufficient combustion and black smoke. And the injector leakage may also cause high temperature in the cylinder, resulting in cylinder liner deformation and piston ring cylinder pulling, and even cracking.

First of all, we should start from the fuel quality, according to ISO standards, we grade the oil according to the particles in the fuel. At present, the national standard oil (petrochina, Sinopec) on the market is basically at a good level, but there are still some areas of oil in poor condition. Mining has always been the "big car" of construction machinery. Shanxi, as a large coal-producing province in China, has a large number of coal mines, which is a typical application condition of construction machinery. Our field analysis of some of the local oil samples showed surprising results: of the six samples randomly selected, five were in the grade of poor oil products, and one even reached the grade of crude oil. If this data is not intuitive enough, then let's do a calculation: Taking the better oil (cleanliness level 18) as an example, the 4μm particles in a 500L tank of fuel oil will reach 1.25 billion, and if it is crude oil, it will reach a staggering 32.5 billion

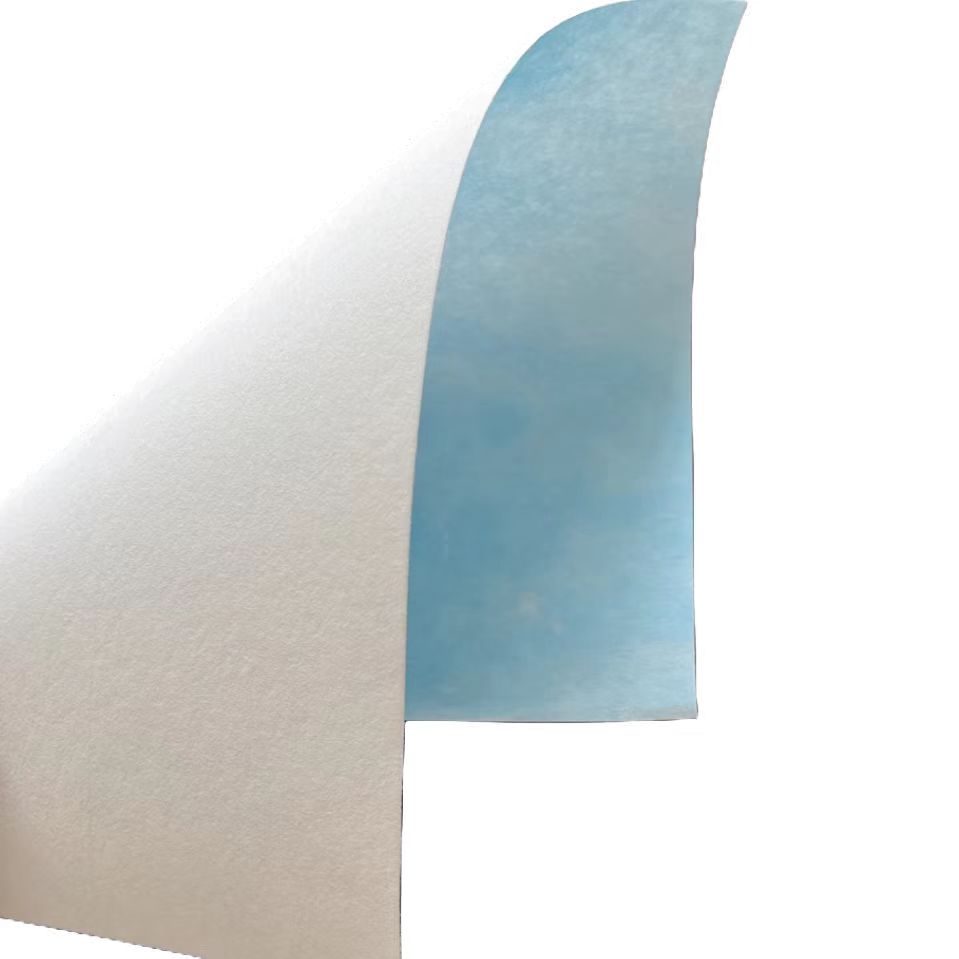

The F8 filter paper produced by Hebei Xinji Blue Sky can effectively protect the engine with its ultra-high filtration efficiency, ensure the safety of the engine during long-term operation of construction machinery, reduce concerns for end users and bring higher profits. Compared with traditional filter materials, the filtration efficiency of nanofilters is at a high level throughout the life cycle, but the filtration efficiency of traditional filter materials will decrease with the increase of service life. At the same time, because the nano-filter material is a full synthetic fiber, it will not be affected by water in the fuel, and it is more stable and reliable in the long-term use process.

Although the particles are small, the harm is huge, and the filter material is small, the effect is huge. The use of more efficient and reliable filter materials can "respond to all changes with no change" in various environments where working conditions and oil conditions are uncontrollable, ensure the normal operation of the engine, reduce failures, so as to ensure the interests of customers, and make the "big guys" fully open!