Production process of automobile filter paper

First, choose raw materials

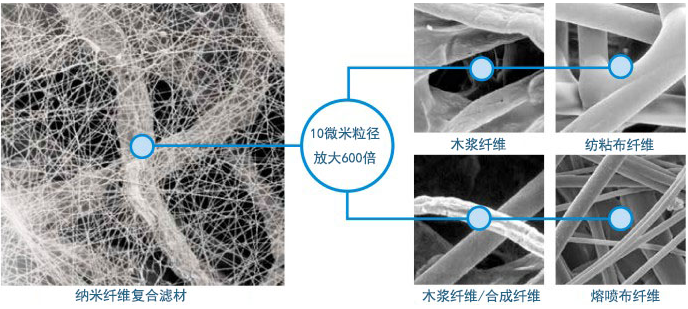

The raw materials of automobile filter paper are usually cellulose, polyamide and so on. Among them, cellulose is the main choice at present, because it has the characteristics of high temperature resistance, no deformation, resistance to acid and alkali corrosion.

Two, beating

Beating the raw material is the first step in the production of filter paper. The purpose of beating is to disperse cellulose and make it more suitable for paper making. Beater can be divided into mechanical beater and chemical beater two ways. Mechanical beating is usually carried out by high-speed cutting, which is suitable for raw materials with short fibers. Chemical beating requires the addition of chemicals, which can disperse the cellulose more evenly.

3. Paper Making

Paper making is the core of filter paper. In the papermaking process, the beaten cellulose is added to the paper machine. The paper maker mixes cellulose with water and passes it through a grid-like sieve, which seeps out the water to form sheets of filter paper. In the process of papermaking, it is necessary to control the content of cellulose, water content, temperature and other parameters. Reasonable parameters can make the produced filter paper have good filtering effect and strength.

4. Processing

Processing is the last step in the production of filter paper. Processing usually includes leveling, cutting, punching and other links. Among them, punching is an important processing method of filter paper, which can improve the filtering effect of filter paper.

5. Influencing factors and future development trends

Factors affecting the production of automotive filter paper include environment, materials, processing equipment and many other aspects. In the future, with the advancement of science and technology, the application of new materials and production technologies will promote the rapid development of the filter paper industry.

In general, the production process of automotive filter paper includes raw material selection, beating, paper making and processing. Reasonable production process can produce good quality filter paper, and the factors affecting the production of filter paper include many aspects such as environment, materials and equipment. In the future, the development trend of automotive filter paper will be closely linked to the development of new materials and production technologies.