Heavy duty vehicle filter paper

Application

The air filter is a key component of the intake system, so the air filter should reduce the dust concentration to an acceptable level, remove large particles, reduce engine noise, reduce airflow obstruction as much as possible, and meet the requirements of the engine

In general, there are two types of air filters, namely wet air filters (oil bath type) and dry air filters (paper air filters). Oil bath air filters can be divided into light load type and medium load type, and dry air filters are classified into light load type, medium load type, heavy load type, overweight load type and long life overweight load type.

The function of the oil filter is to filter out metal debris, mechanical debris and oil oxide in the oil. If this debris enters the lubrication system with the oil, it will increase the damage of the engine parts, and may block the oil pipe or oil passage

During the operation of the oil engine, metal debris, dust, carbon deposits oxidized at high temperature, colloidal sediments, and water are constantly mixed with the lubricating oil. The role of the oil filter is to filter out these mechanical impurities and glia, ensure the cleanliness of the lubricating oil, and extend its service life. The oil filter should have strong filtration capacity, small flow resistance, long service life and other properties. The general lubrication system is equipped with several filters with different filtration capacity - the collector filter, the coarse filter and the fine filter, respectively in parallel or series in the main oil passage.

(The full-flow filter in series with the main oil passage is called, and the lubricating oil is filtered by the filter when the engine is working; Parallel with it is called the separator filter). The coarse filter is connected in series in the main oil passage for full-flow;

The fine filter is shunt in parallel in the main oil passage. Modern automobile engines generally have only a collector filter and a full-flow oil filter. The coarse filter removes impurities with a particle size of 0.05mm from the oil, and the fine filter is used to remove fine impurities with a particle size of 0.001mml or more.

The fuel filter is connected in series to the pipe between the oil pump and the throttle body inlet. The function of the fuel filter is to remove solid debris such as iron oxide and dust contained in the fuel to prevent the fuel system from clogging (especially the fuel nozzle). Reduce mechanical wear, ensure stable engine operation and improve reliability. The structure of the fuel oil is composed of an aluminum shell and a bracket with stainless steel, and the bracket is composed of high efficiency filter paper, and the filter paper is chrysanthemum-shaped to increase the circulation area. The EFI filter cannot be used in common with the chemical oil filter. Because the EFI filter often withstand 200-300kpa fuel pressure, the pressure strength of the filter is generally required to reach more than 500KPA, and the oil filter is not necessary to achieve such a high pressure.

One near the fuel tank or on the girder is the coarse filter; The other is near the oil pump on the diesel engine, which is the fine filter.

Filter element separates solid particles in liquid or gas, or make different material components fully contact, speed up the reaction time, can protect the normal work of equipment or clean air, when the fluid enters the filter element with a certain size of the filter screen, the impurities are blocked, and the clean flow flows through the filter element.

The role of diesel filter is very important, the sulfur content of domestic diesel is very high, if there is no diesel filter, the sulfur element will directly react with water to produce sulfuric acid, thus corroding the internal parts of the engine. Therefore, the diesel filter is extremely important.

The working principle of the oil-water separator for diesel vehicles

1. The oily water is sent to the oil-water separator by the sewage pump, and the large particle oil droplets of the diffusion nozzle float on the top of the left oil collecting chamber. The sewage containing small oil droplets enters the lower part of the corrugated plate coalesce and polymerizes part of the oil droplets into larger oil droplets to the right oil collecting chamber.

2. the sewage fine filter containing smaller particles of oil droplets, out of the water impurities, into the fiber polymerizer, so that the small oil droplets polymerization into larger oil droplets and water separation. The clean water is removed through the discharge port, the dirty oil in the left and right oil collecting chamber is automatically removed through the solenoid valve, and the dirty oil separated in the fiber aggregator is removed through the manual valve.

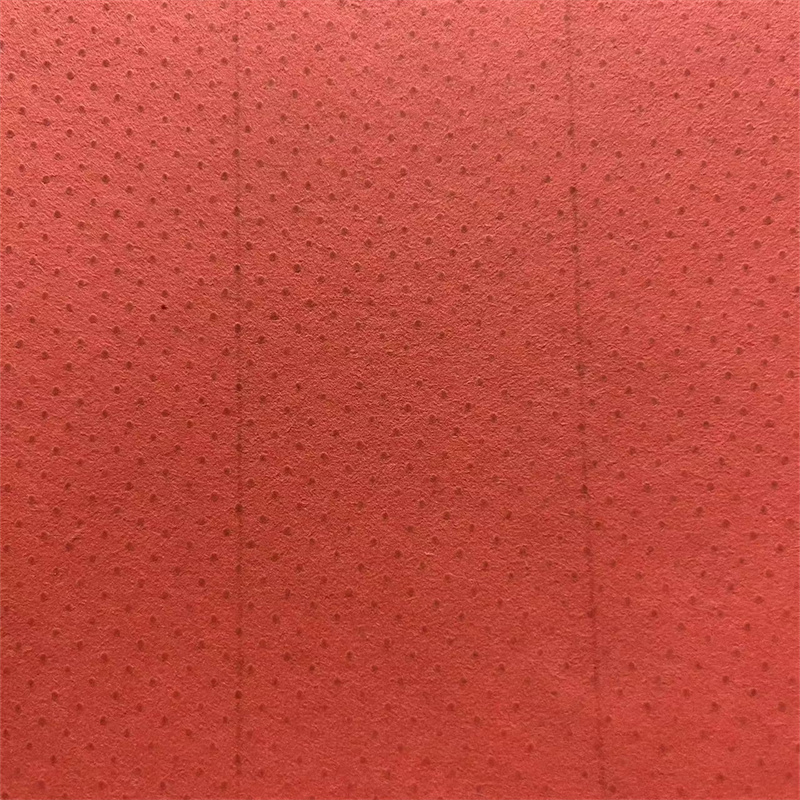

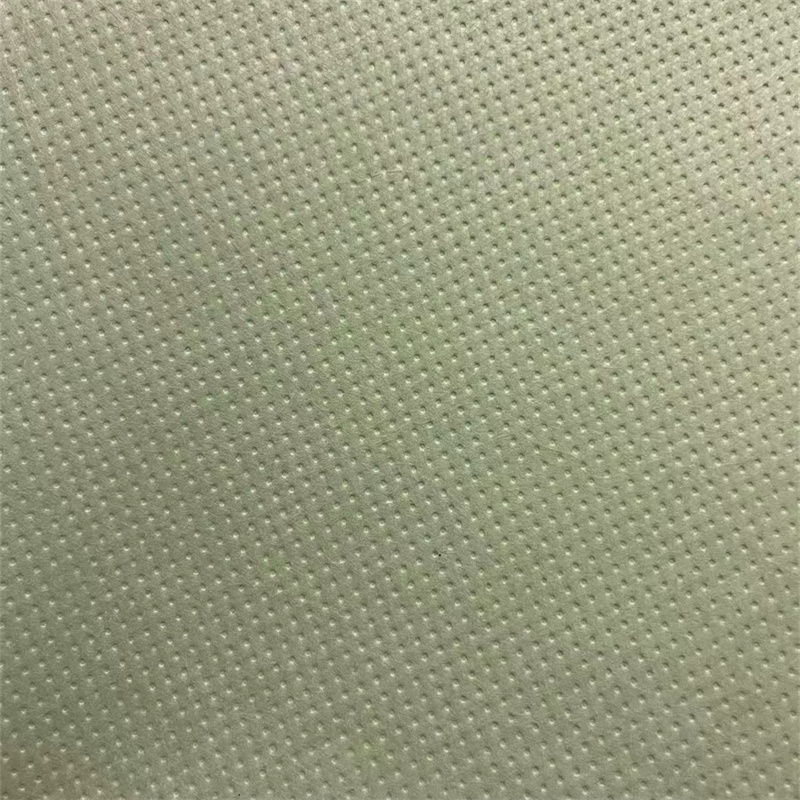

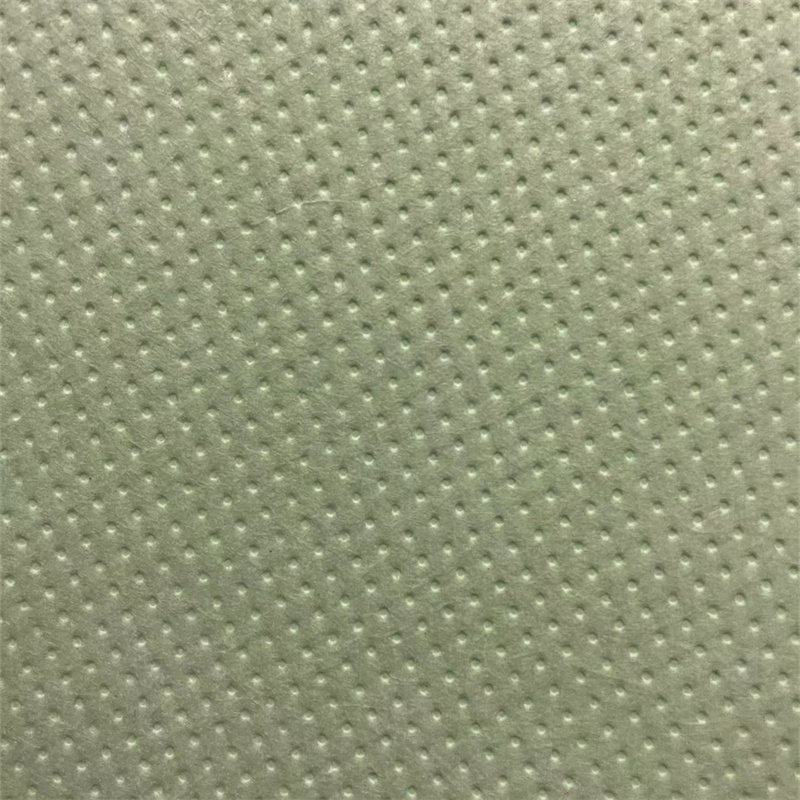

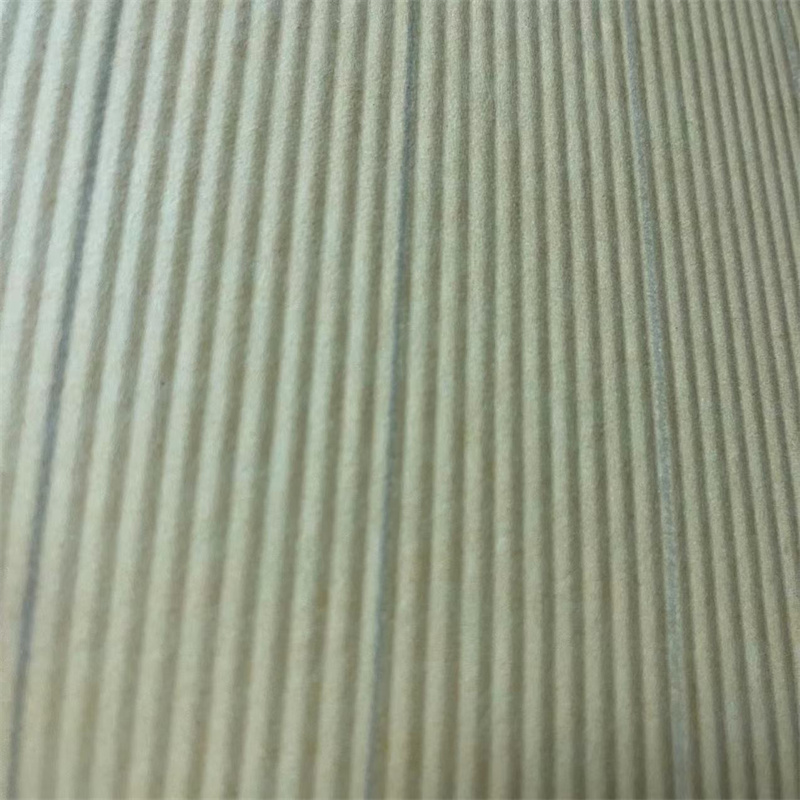

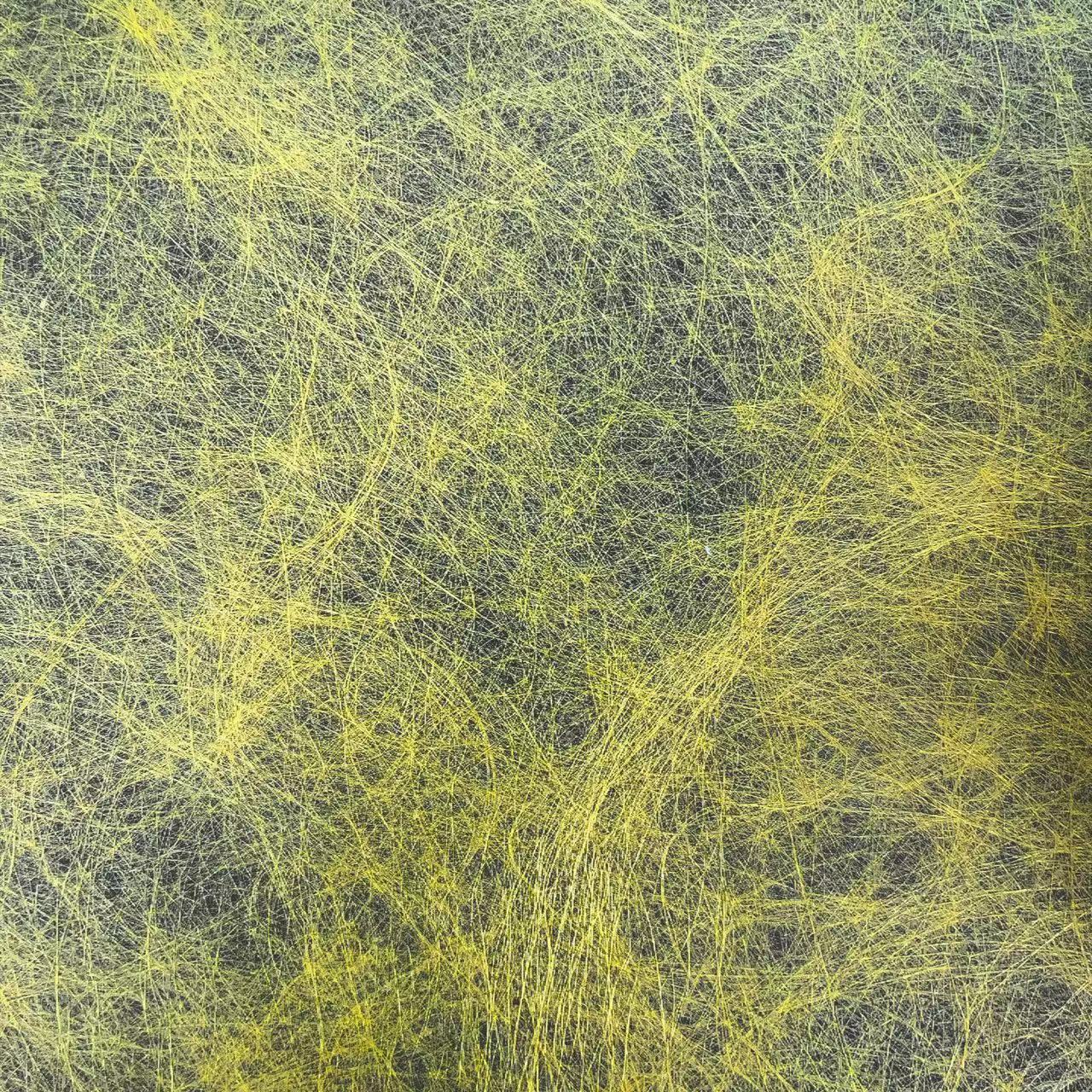

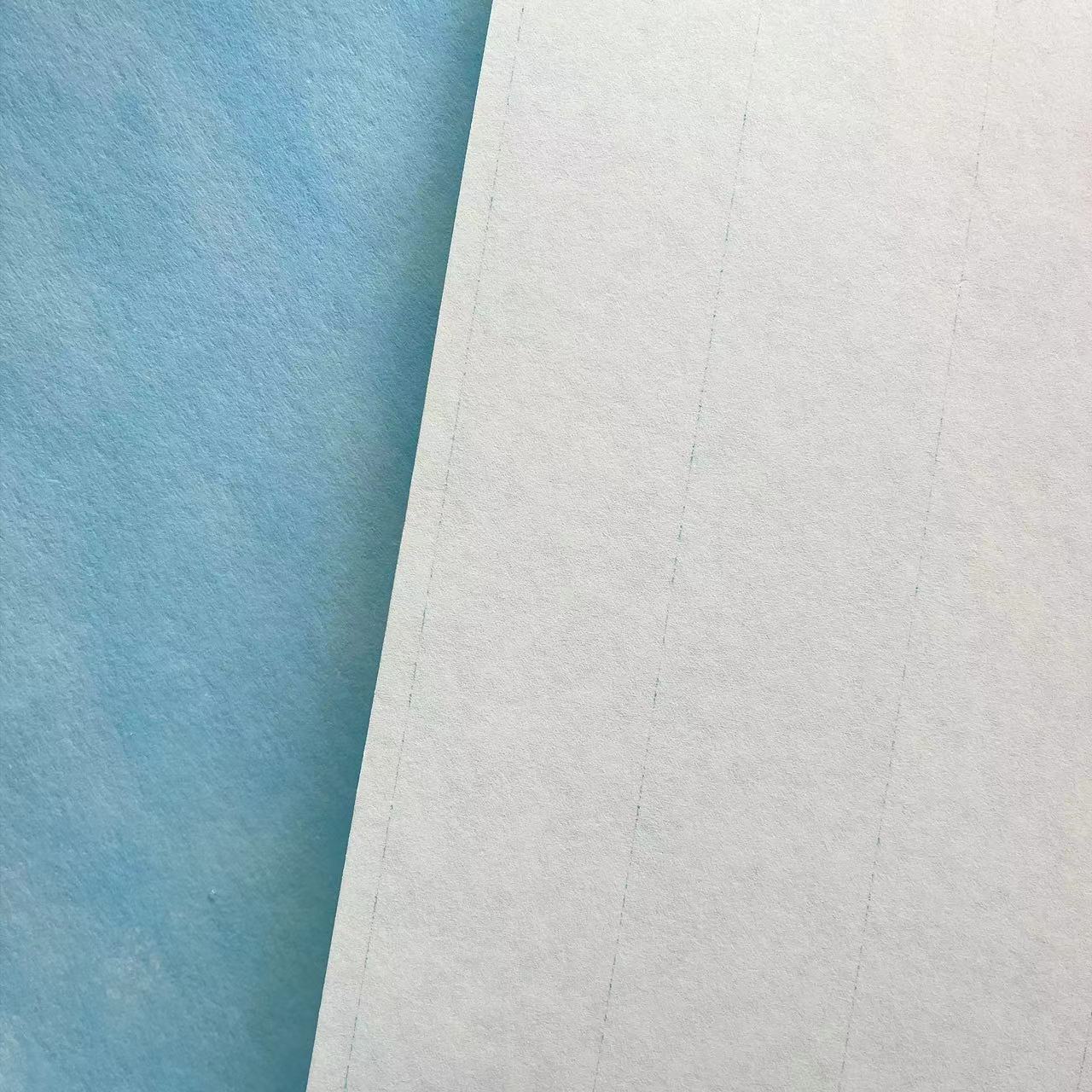

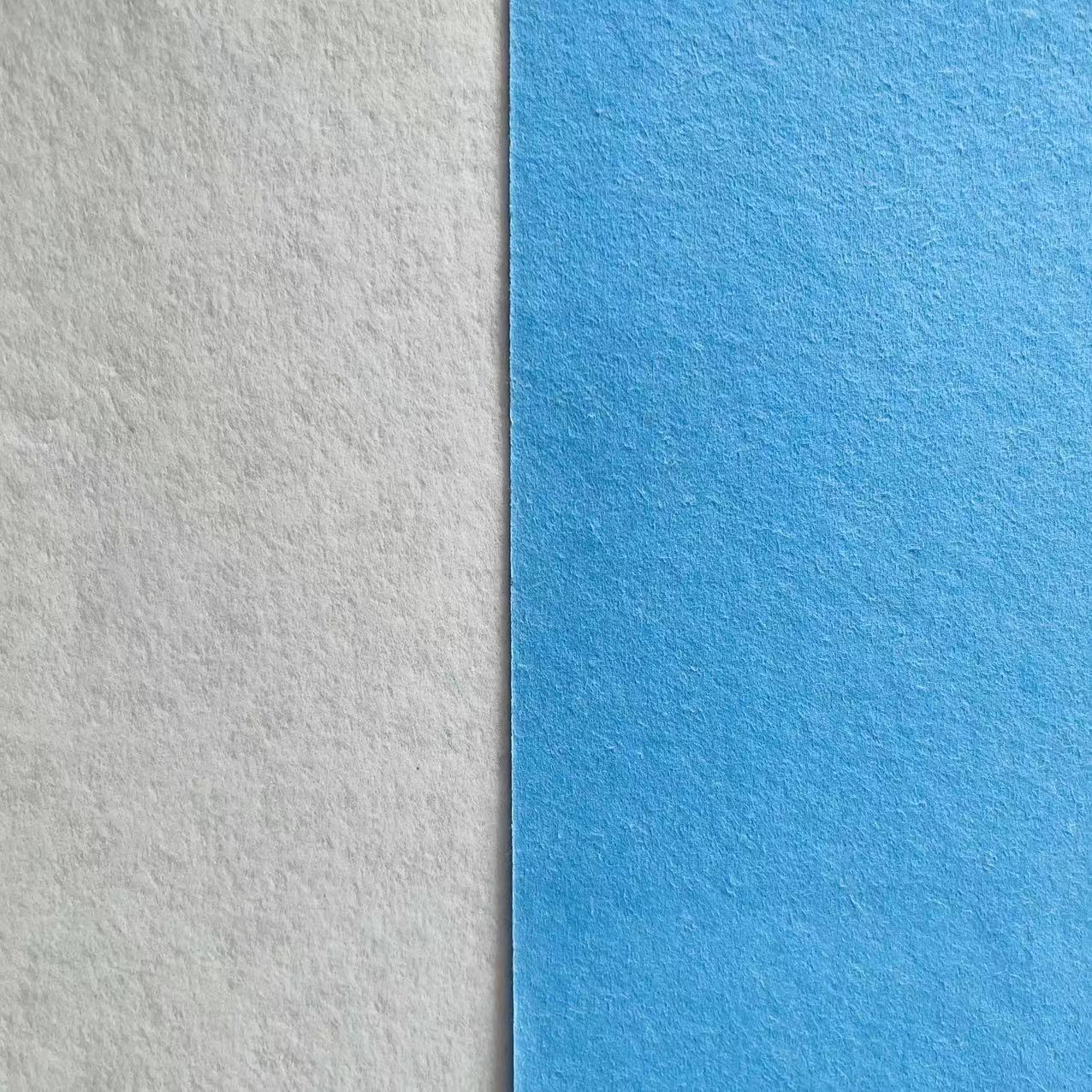

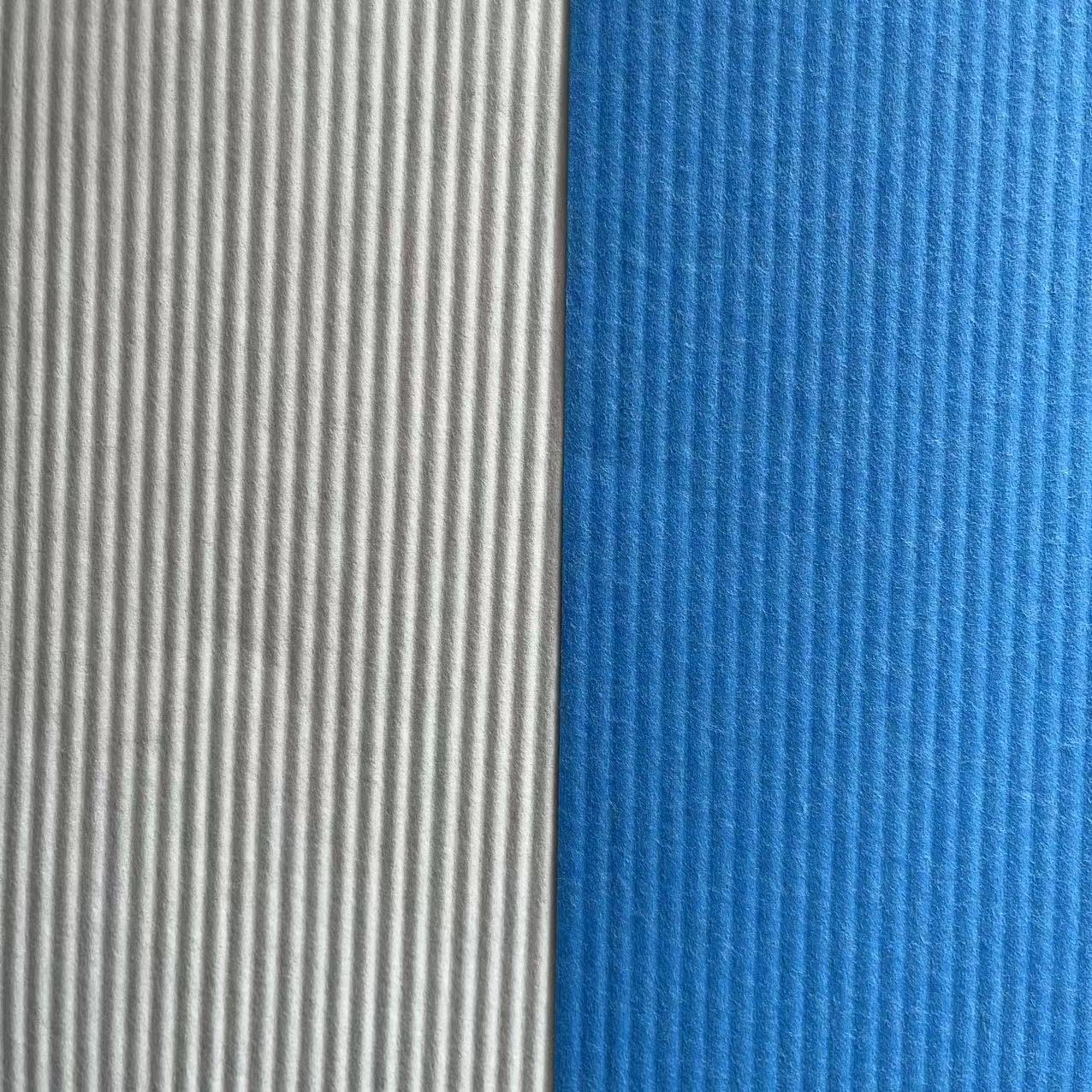

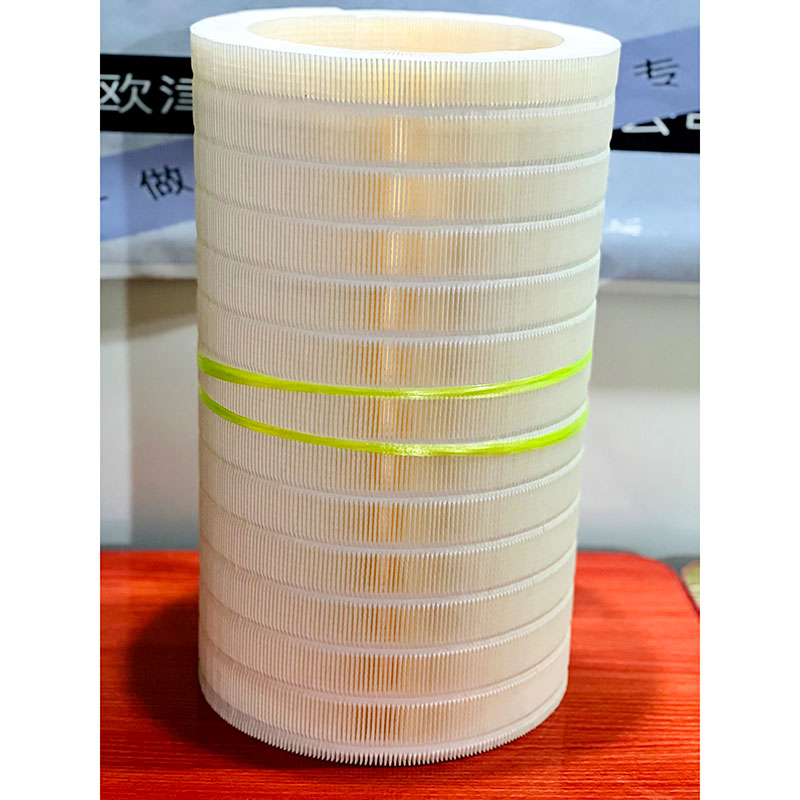

Air Filter Paper For Heavy-Duty

Model number: LWK-115-160HD

| Acrylic resin impregnation | ||

| Specification | unit | value |

| Grammage | g/m² | 115±5 |

| Thickness | mm | 0.68±0.03 |

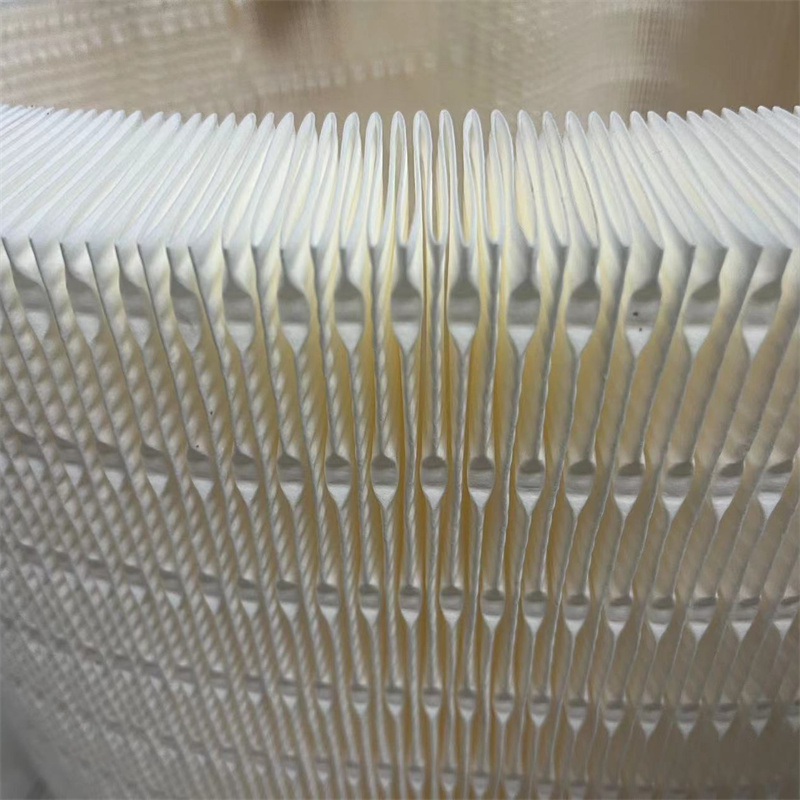

| Corrugation depth | mm | 0.45±0.05 |

| Air permeability | △p=200pa L/ m²*s | 160±20 |

| Max pore size | μm | 39±3 |

| Mean pore size | μm | 37±3 |

| Burst strength | kpa | 350±50 |

| Stiffness | mn*m | 6.5±0.5 |

| Resin content | % | 22±2 |

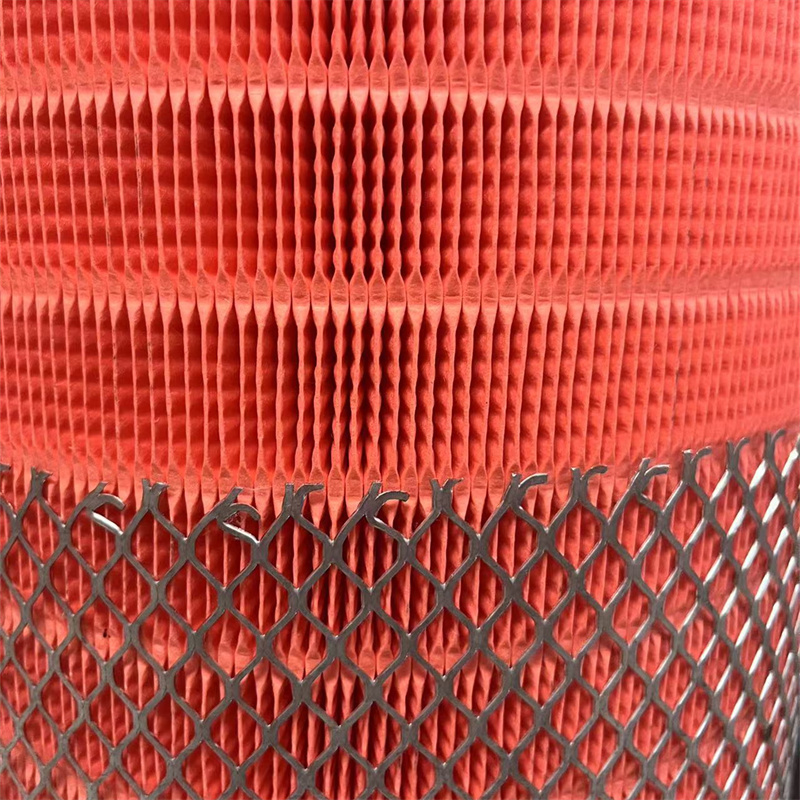

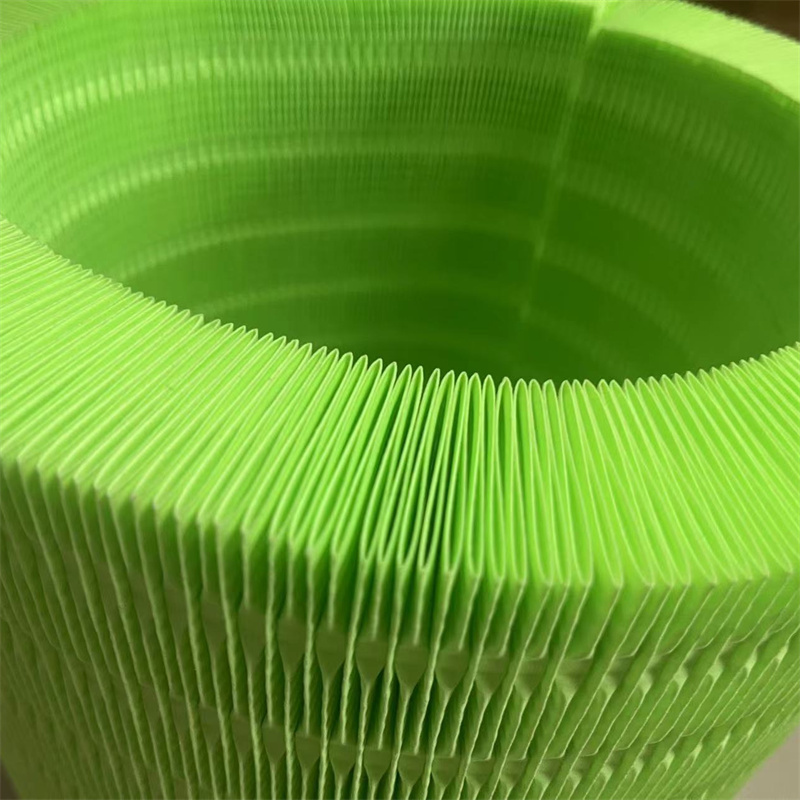

| Color | free | free |

| Note: color, size and each specification parameter can be changed as per customer’s requirement. | ||

more options